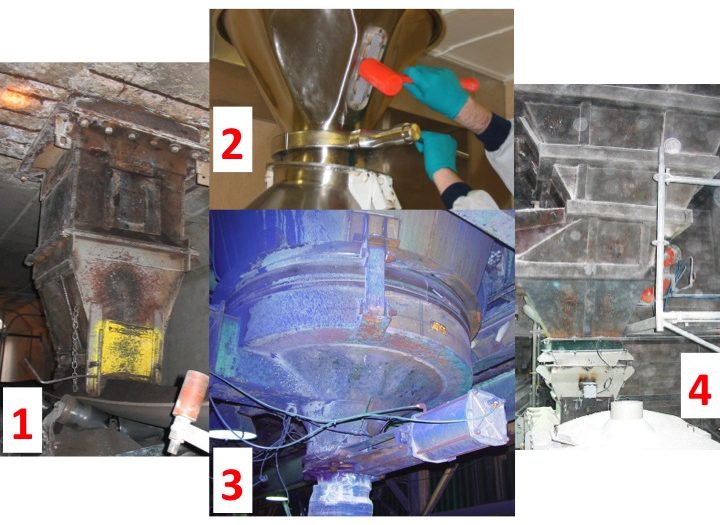

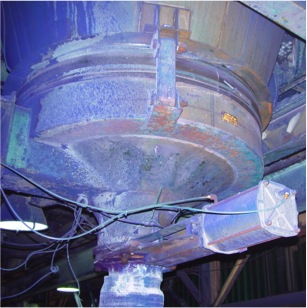

Chances are high that if you are reading this blog, you have probably come across an “ugly hopper”. Included in this blog post are some examples of “ugly hoppers” I have come across. It has been said that “beauty is in the eye of the beholder”; my interpretation of “ugly” can be classified into hopper damage and poor operating behaviors.

Hopper damage

- Hammer “rash”

- Buckling, bulging, warping

- Corrosion or erosion (from abrasive wear)

- Weld fracture, cracks, and other signs of fatigue

Poor operating behaviors

- No flow or erratic flow

- Fine powder flooding or flushing

- Segregation (by particle size, shape, or density)

- Discharge rate restrictions

Though the “ugly hopper” you observed may have many of the “physical characteristics” above, it may not necessarily be heavily impacting the “bottom line” — the hopper may just need some basic maintenance. However, if the “ugly hopper” is experiencing poor operating behaviors, then high costs may be incurred due to production inefficiencies, increased labor requirements, and poor product quality.

Our engineers perform on-site inspections of powder and bulk solids handling equipment every week of the year throughout the world. We have come across many thousands of “ugly hoppers” whereby poor operating behavior is often the root cause of the physical damage. On a moment’s notice, our experts can travel to your facility to help rapidly determine a cost-effective solution to poor material handling, processing, or conveying problems.

So, I now ask for your input – which hopper above is the “ugliest”? Please reply with your vote. I will let you know the “winner” in a future blog!

If you have a photo and short story of an “ugly hopper” you would like to share, please send it to epmaynard@jenike.com.

Thanks!