Open House – Jenike & Johanson Canada is Turning 50!

Open House – Jenike & Johanson Canada is Turning 50!

Feeders Overview

A feeder is essential for controlling the flow rate of bulk solids from silos, bins, and hoppers. The feeder is an integral part of a storage system because it can have a major impact on the flow pattern in the storage vessel – it can either maintain reliable material flow or induce poor flow, segregation, or flooding of fine powders. Proper selection of a screw, belt, rotary valve (rotary air lock), or vibratory feeder should be integrated into the material handling system design early in the process.

Jenike & Johanson specializes in feeder assessment, whether troubleshooting problems or implementing a new design for a challenging bulk material. Review our solution approach below, which is based on proven powder and bulk solids theories, material flow properties, and decades of experience designing and integrating reliably operating feeders.

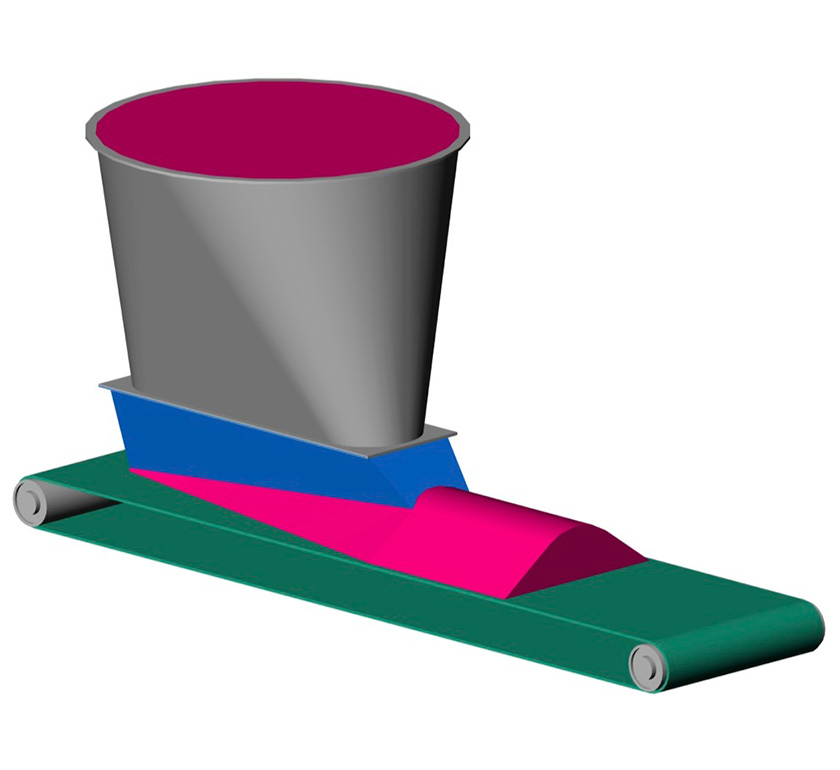

Belt feeder conceptual design for uniform flow.

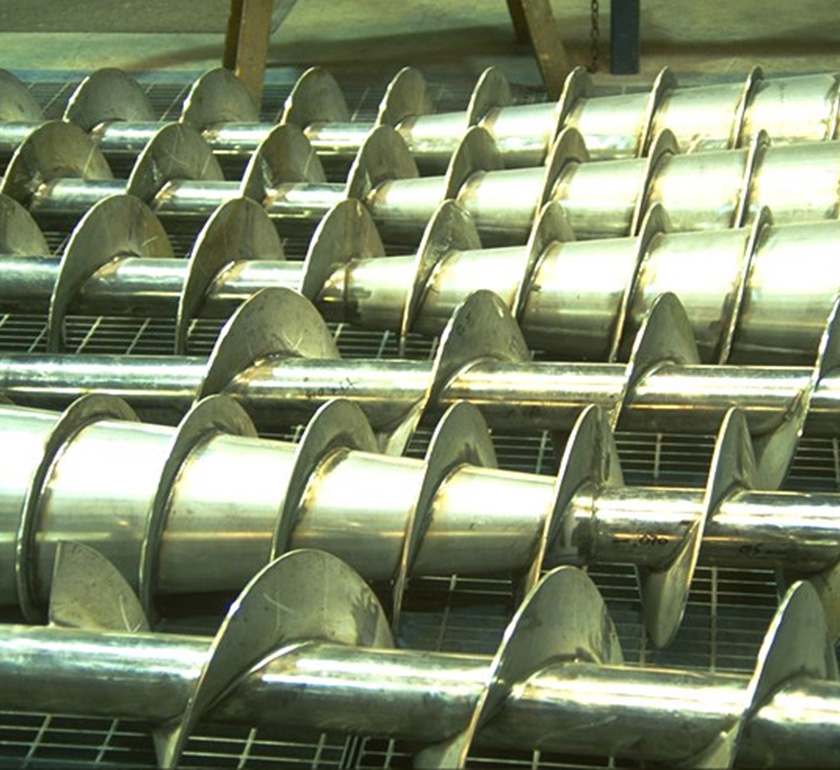

Custom designed mass flow screw feeders.