Cement Industry

Cement quality relies upon consistent kiln feed and reliable raw mix formulation.

The Cement industry provides the main building material for commercial, residential, and governmental projects involving infrastructure (e.g., roads, bridges, tunnels).

Most new plants or line expansion projects are seeking techniques to reduce production costs, while minimizing adverse environmental impact during cement production. To meet ever increasing demands, cement kilns must have consistent, reliable feed of raw materials, such as limestone, clay, sand, mill scale/iron ore, and bauxite. Though dry process cement plants are advantageous over wet process plants due to significant energy savings, they experience additional material handling problems during feeding, milling, and calcination. Cement plants continue to seeks ways to reduce fossil fuel consumption through use of alternative fuels. Clinker substitution with limestone or pozzolanic additives is now a common practice.

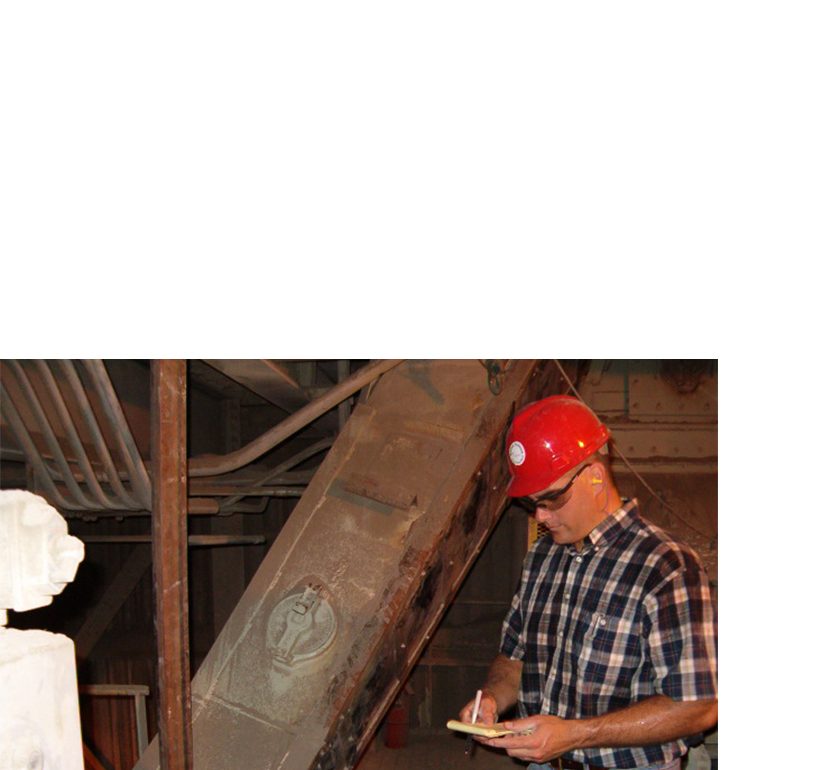

A cement plant

A stockpile of cement next to silos.