Open House – Jenike & Johanson Canada is Turning 50!

Open House – Jenike & Johanson Canada is Turning 50!

Plastics

Poor flow can cause high volatiles concentration, caked resin, and cross-contamination.

The Plastics industry provides important engineering materials for a myriad of applications, including consumer products (e.g., cellular phones, televisions, electronics), packaging, automotive (e.g., body panels, dashboards, lenses), and foods (e.g., films, containers).

Reliable material handling is vital in the Plastics industry to achieve typical manufacturing practices of six sigma operation, process automation, lean production, efficiency optimization, and debottlenecking. These goals can be upset by poor plastics solids flow behavior and lack of proper material handling equipment design and process development.

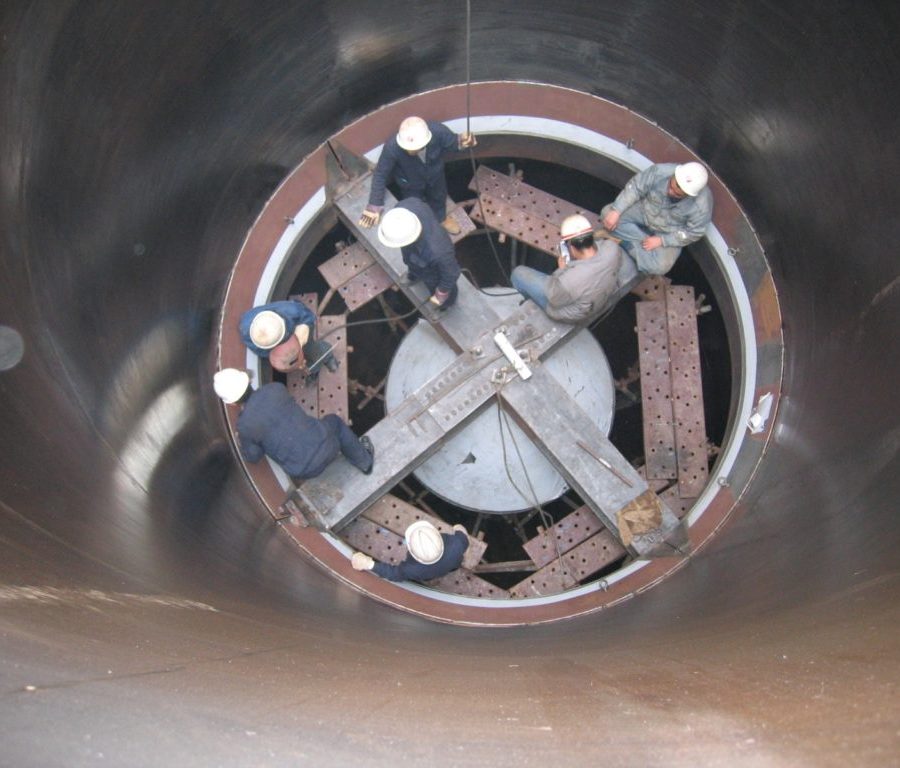

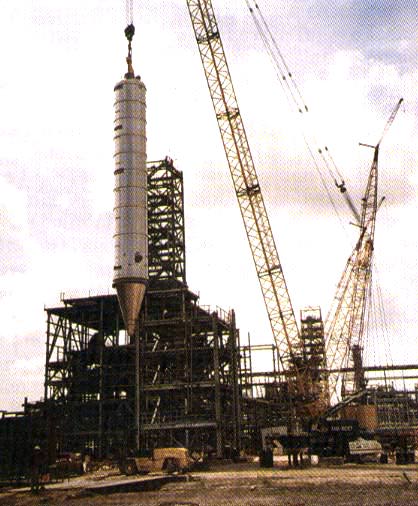

Silos in a plastics plant.

Extruder feed hopper.