Open House – Jenike & Johanson Canada is Turning 50!

Open House – Jenike & Johanson Canada is Turning 50!

Overview

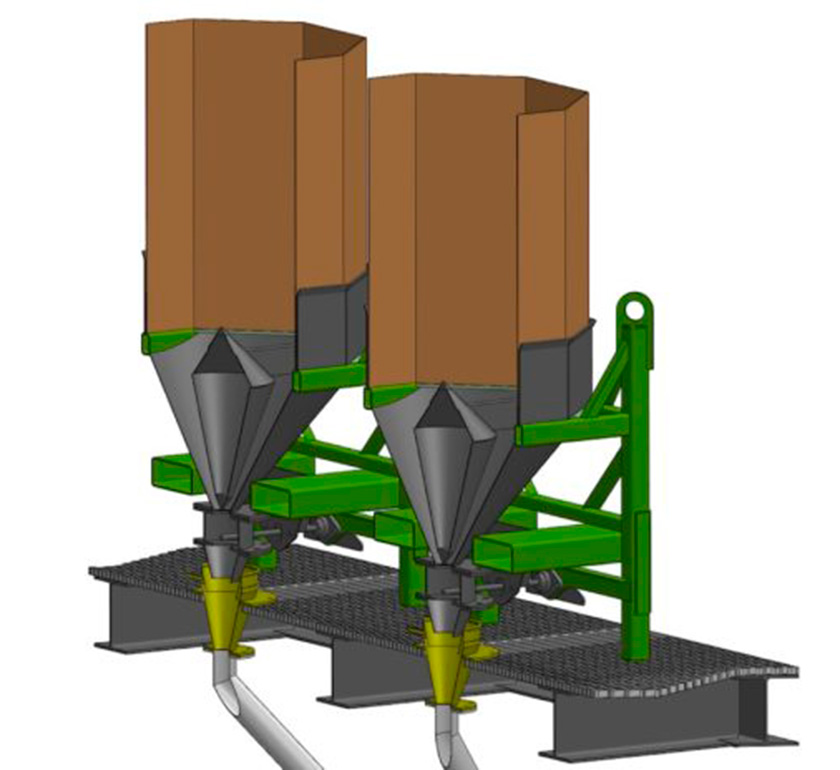

Powdered Metals

Quality green compacts require uniform feed of well-blended, non-segregated powder.

The P/M industry (Powdered Metals/ Cermets/ Intermetallics) is diverse and includes applications for automotive, aerospace, medical/dental, electronics, defense, hardware, and appliances.

The vision of this industry is to continuously seek out new materials, and innovative techniques to manipulate powdered metals, to enable its customer base to solve increasingly difficult problems related to energy conservation, reliability, size and weight reduction, bio-compatibility, product performance, and cost.

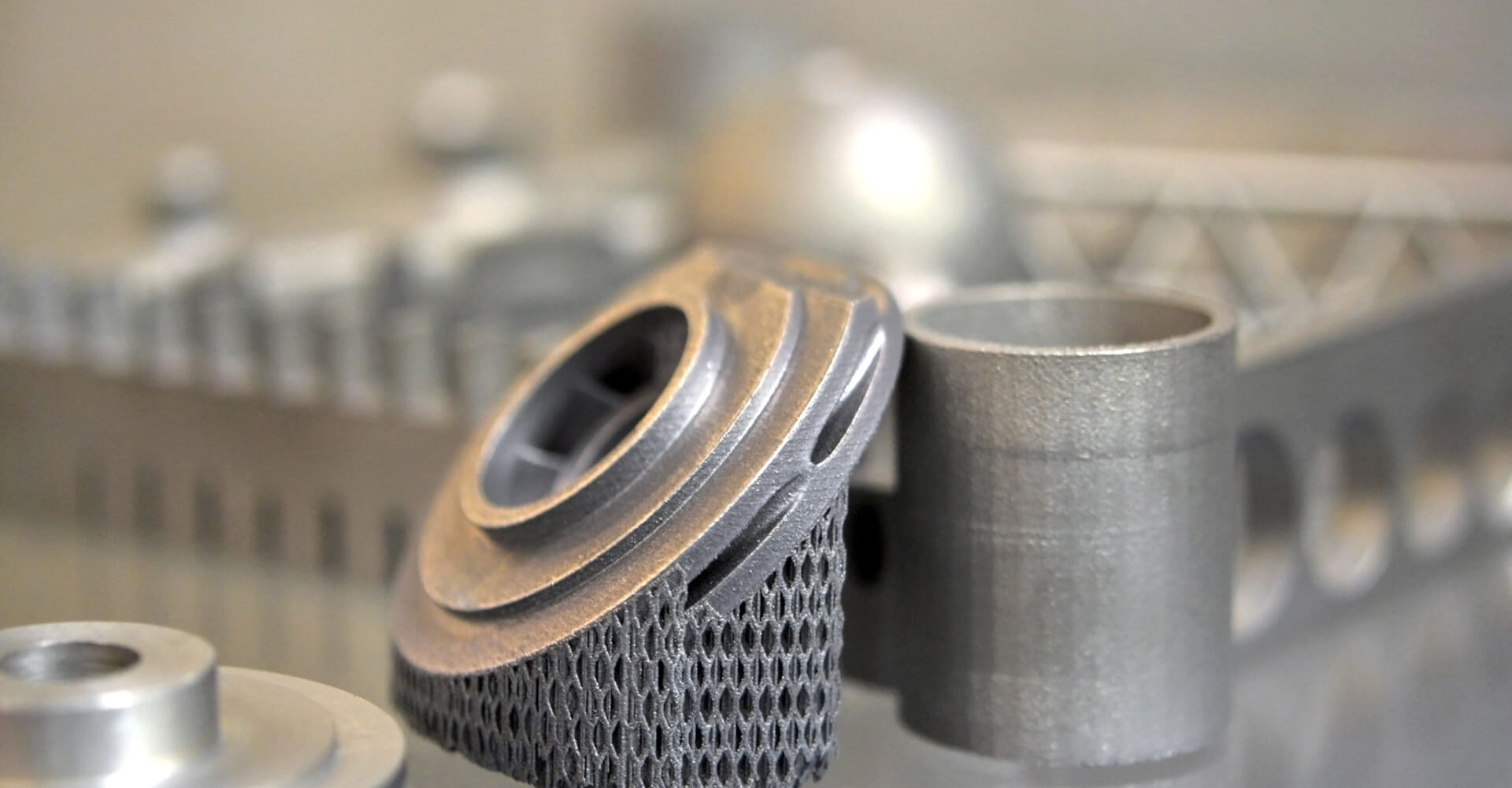

Powdered metals parts.