Overview

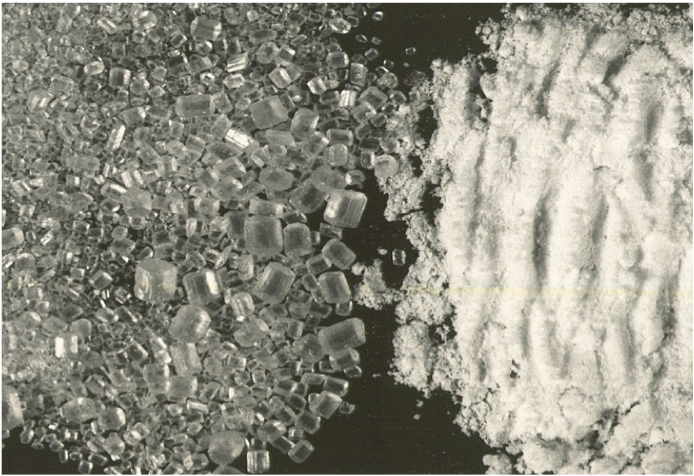

What is Product Non-Uniformity?

Product non-uniformity is used to describe situations in which a product does not meet quality-control metrics set by your company, your customers, or a regulatory agency.

It can mean a variety of different things for different industries. For example, tablets produced by a pharmaceutical company may not have the required mass or content uniformity. Or, a box of cereal flakes may contain too many fines or crumbs.

Particle attrition caused form pneumatic conveying.

Inspecting grain for non-uniformity.

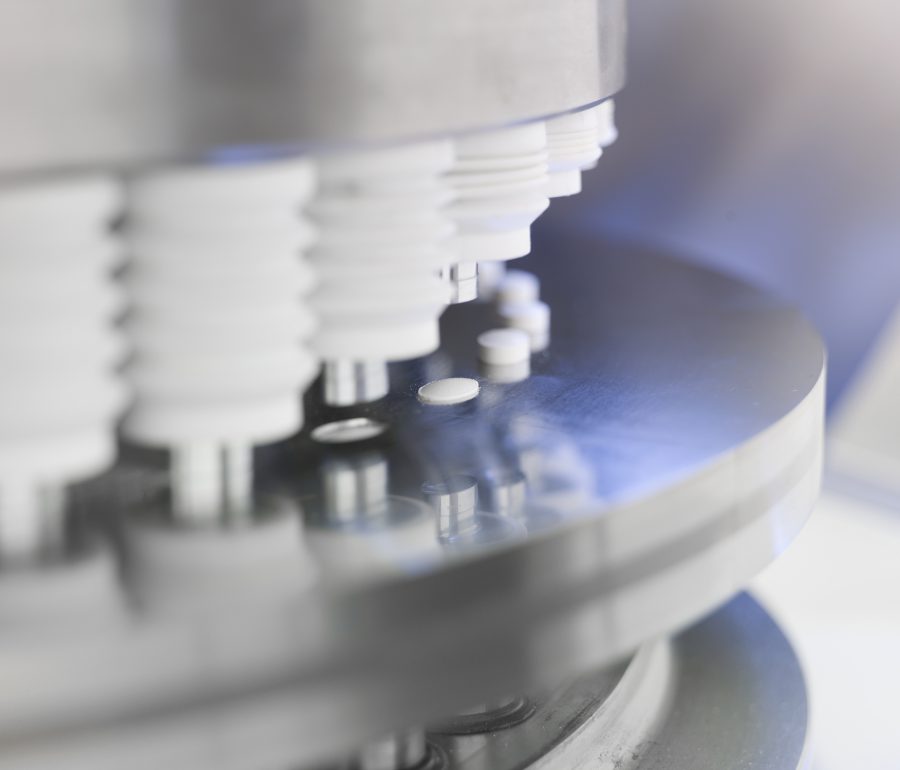

A tabletting press

Vertical multi-head weigher packaging machine for chips to help ensure accurate dosing and uniformity.

Corn snacks passing through a tumbling machine to support product uniformity.