Overview

Why Powder Caking Testing?

Caking occurs when particles agglomerate and form solid lumps or masses.

Caking is usually undesirable, resulting in customer complaints, rejected product, and additional processing steps needed to delump the material.

Though caking commonly occurs with many packaged powders, it can also occur in poorly designed silos, hoppers, and other equipment that allows material stagnation. Preventing caking can be difficult if factors contributing to these problems are not well understood.

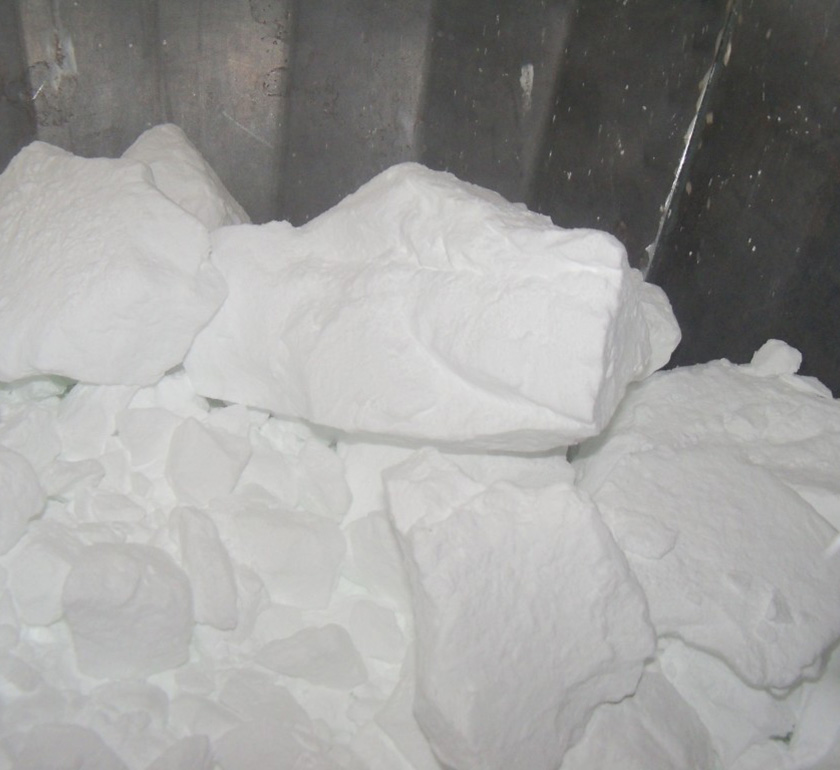

Caked material within a drum.

This brown sugar shows caking.

Lumpy, caked material.

Caking within a sulfur stockpile.

Caking within a salt stockpile.