The Need

Dominion’s Mt. Storm ( Dominion ) Power Station in West Virginia has three coal-fired units and a gross generating capacity of about 1680 MW. Like many other power plants built before 1980s, Mt. Storm Power Station was constructed using bunkers designed for relatively easy-flowing, lump coal. As the coal supply changed to finer and more moist coal, which has more cohesive strength, the Power Station began experiencing frequent arching and ratholing in fuel bunkers. The station could have 70 feeder pluggages in a shift. As a result, the station had to burn stabilizing oil, which was very expensive.

The Solution

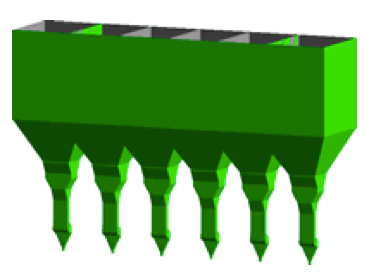

Dominion contacted Jenike & Johanson (J&J) for addressing the coal handling problems. J&J tested samples of the coal that the Station was handling to determine flow properties. The test results revealed that the coal handling problems at Mt. Storm were occurring as a result of funnel flow in the fuel bunkers. J&J recommended bunker modifications to achieve mass flow through a series of wedge-shaped hopper sections. Dominion asked J&J to consider expanded flow design, where only a part of the bunker geometry would be modified to mass flow. Dominion agreed that the benefits of expanded flow solution would greatly outweigh the costs of not implementing any solution at all.

The Result

When modifications recommended by J&J were first implemented at Unit 2, the benefits were quickly apparent. Operators reported more reliable operation of the Unit; the arduous task of clearing pluggages was nearly gone. Then, Dominion went ahead to implement the modifications at Units 1 and 3. These modifications solved the flow problems at Mt. Storm.