Clients sometimes ask me if a storage tank that was designed – and often being used – for storing a liquid can be converted to store a bulk solid. Basically they are asking, “Will the material-induced loads exerted by my bulk solid be less than those exerted by my liquid?”

There’s not a simple “yes” or “no” answer to this question. As is often the case with questions like this, the answer is, “It depends.”

The first thing to recognize is that liquid storage tanks are usually designed to API Standard 620 “Design and construction of large, welded, low-pressure storage tanks”. That Standard only applies to tanks designed to store liquids, and it specifically does not cover the storage of bulk solids.

Next, the first thing to consider is the density of the bulk solid compared to that of the liquid for which the tank was designed. With both liquids and bulk solids, pressures acting against a tank’s wall vary linearly with density: double the density, double the pressures.

Assuming that the bulk solid’s density is no greater than that of the liquid, the next thing to consider is the tank’s vertical wall. A liquid exerts only normal pressures, i.e., pressures that act perpendicular to a tank’s walls. These pressures generate hoop (i.e., circumferential) tensile stresses in a tank wall. A bulk solid exerts both normal pressures and also shear tractions downward along a tank’s walls. These shear tractions generate vertical compressive stresses in the wall than can cause it to buckle – much like an empty soda can that collapses when you push down on its top with your hand. Indeed, the ability of a metal tank to resist compressive buckling governs its minimum required wall thickness – not its ability to resist hoop tension. Needless to say, compressive buckling never enters into consideration when a tank is being designed to store a liquid.

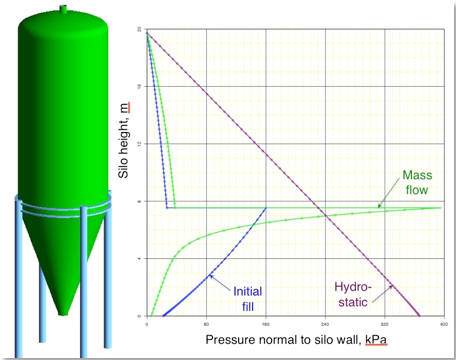

Next, one needs to consider the flow pattern in the tank when a bulk solid is placed in it. A mass flow pattern results in much higher normal pressures and shear tractions just below the top of the hopper than a funnel flow pattern. As can be seen in the accompanying graph, the magnitude of this pressure peak can exceed hydrostatic pressure by a considerable margin.

Next, one needs to consider the flow pattern in the tank when a bulk solid is placed in it. A mass flow pattern results in much higher normal pressures and shear tractions just below the top of the hopper than a funnel flow pattern. As can be seen in the accompanying graph, the magnitude of this pressure peak can exceed hydrostatic pressure by a considerable margin.

Another issue that may need to be considered is eccentric loads. Discharging a liquid from a side opening does not change the pressure distribution against a tank’s wall. Doing so with a bulk solid can – and often does – have a major effect: lower pressures where the flow channel intersects the tank wall, higher pressures around the rest of the circumference. This can result in significant flattening of metal walls and vertical cracks in reinforced concrete walls. In fact, eccentric loading of bin and silo walls is one of the major causes of failure.

Finally, the design of structural components of a bulk solids storage vessel (i.e., its cylinder, hopper, and support system) must take into consideration several load combinations and patterns, each of which affects, predominantly, only one or a few components. This is unlike most other structural systems where their structural components are designed for a single load combination (worse case scenario). Therefore, understanding the behavior of each structural component as well as the loads affecting it is essential to ensure the structural integrity of a bin or silo storing a bulk solid.

So, “It depends!” There are many factors that must be considered before converting a liquid tank to store a bulk solid. To learn more contact us and we can help determine if the repurposing of a liquid storage tank to bulk solids is the right course of action.

Now that we’ve covered some basic structural considerations, the next question to consider is, “Will my bulk solid reliably discharge from my tank at the rate and consistency that I require?” That’s a question for another day…