ALTA

ALTA

Overview

Physical Process & Pilot Scale Modeling

Are you developing a unique process or design for a challenging bulk solid? Jenike & Johanson has the experienced staff, knowledge, and specialized tools to perform both physical and real-world analytical modeling studies. We understand the importance of making sure the models are accurately scaled geometrically and with respect to bulk material flow properties.

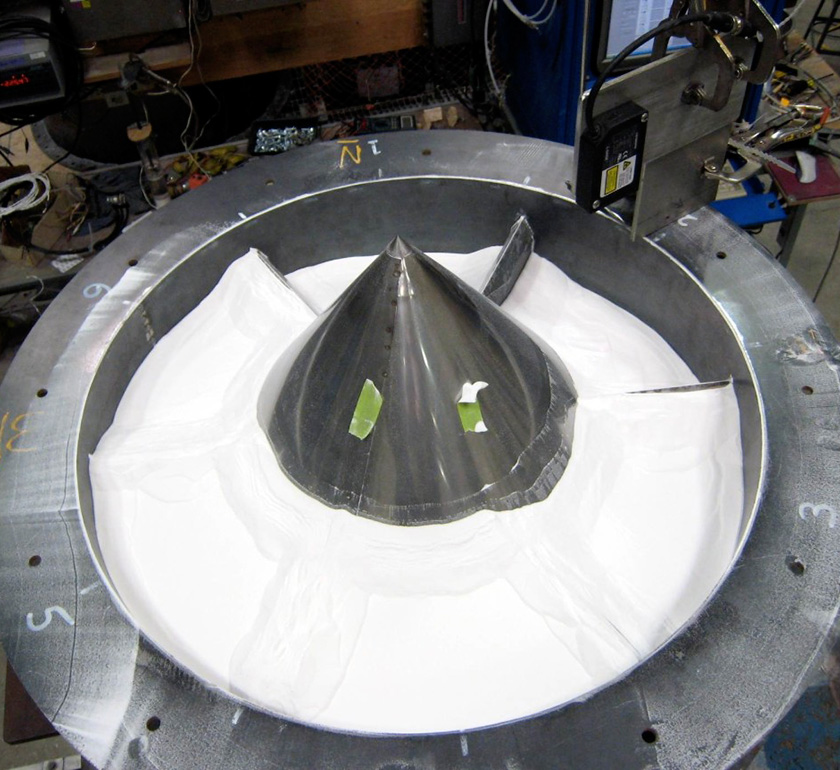

Modeling of a complex hopper.

Modeling of a bullet insert for uniform powder flow.

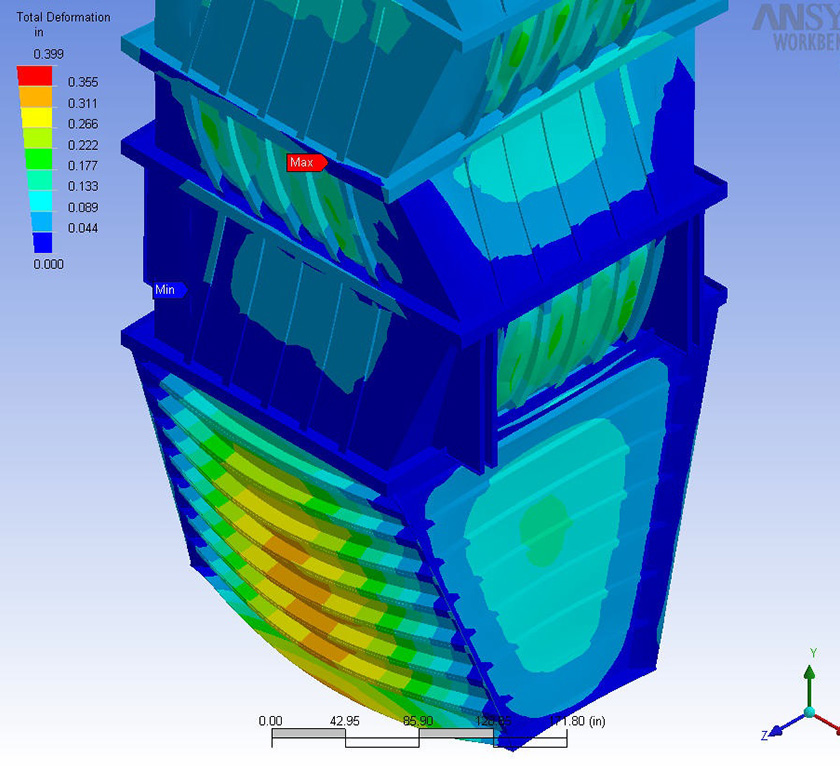

Results of a structural FEA (Finite Element Analysis).