One Day @ J&J – Massachusetts

One Day @ J&J – Massachusetts

3D Particle Scanner

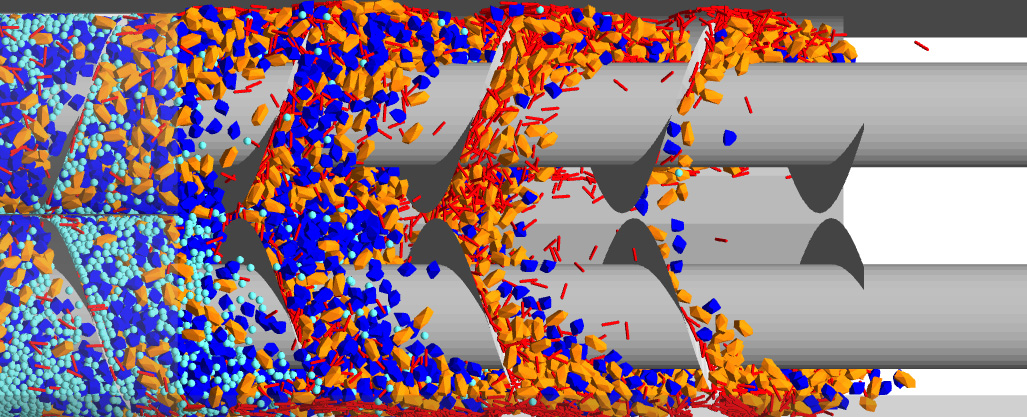

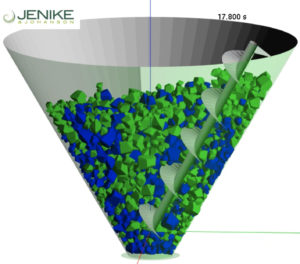

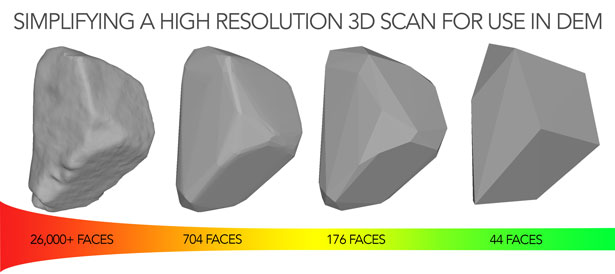

We can accurately model particle shape using our 3D particle scanner and our polyhedral algorithm in our code. Computational speed does matter for efficient engineering, thus, using polyhedral algorithms with particles having extraneous facets is not beneficial to the DEM analysis because every facet must undergo tracking and calculations for acceleration, velocity, position, and impact, torque, sliding, etc. We’ve optimized our DEM code to use polyhedral geometries that reflect you material processing so you get prediction results that can help engineer improvement to your bottom line.