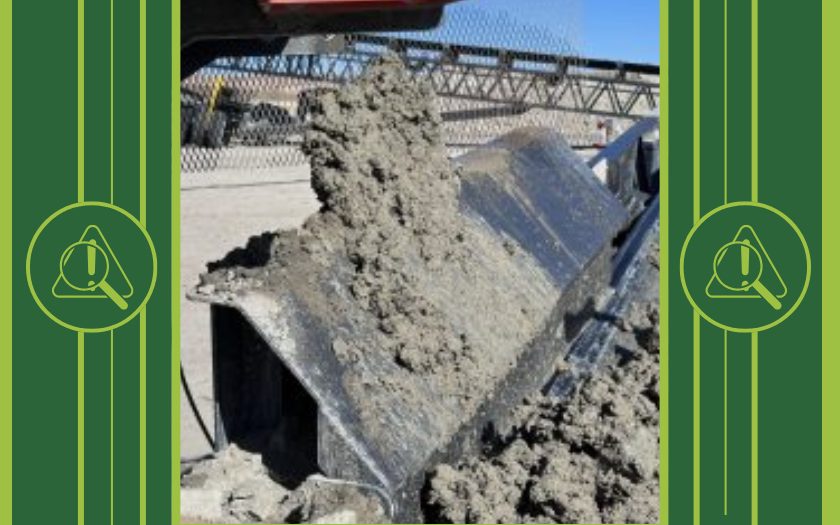

Any interruption in ore flow can have significant operational consequences. Hang-ups within chutes or transfer points restrict throughput, increase downtime, and elevate the need for manual intervention. In bulk solids handling, hang-ups occur when ore sticks, bridges, or forms plugs that block the normal path of flow. Because mines depend on steady, predictable flow, these disruptions translate directly into reduced throughput, revenue loss, and elevated operational risk. Identifying the conditions that promote hang-ups is therefore essential to designing systems that perform reliably across the entire ore-handling chain.

What Causes Hang-Ups in Ore Flow Systems

Hang-ups rarely happen by chance. They form where the characteristics of the ore and the geometry of the system fall out of sync. Common contributing factors include:

- Material behavior- Changes in moisture, fine particle content, clay content, or particle shape can make an otherwise free-flowing ore cohesive or sticky. As a result, fine-rich or damp material tends to stick to surfaces and cause buildup that can result in plugging that restricts movement.

- Design and geometry- Sharp corners, shallow slopes, and rough liners slow material as it moves through a chute. Misaligned transfer points, steep impact angles, or high-impact drop heights can cause the flow stream to strike walls, rebound, and build up along edges.

- Operational conditions- Surges in feed rate, inconsistent maintenance, or worn liners gradually change flow behavior and lead to recurring blockages.

- Environmental changes- Seasonal moisture, freezing, or temperature variations can alter flow properties and cause temporary flow problems.

A hang-up often signals that the material, equipment, or operating conditions have changed and the bulk solids handling system must be updated accordingly.

Ore Flow Troubleshooting: Finding the Root Cause

The most effective way to address hang-ups is through a structured, evidence-based troubleshooting process:

- Locate the blockage – Identify precisely where material is building up, be it at the entry, mid-section, a corner, or the discharge point. Installing a video camera looking into the chute can be a safe way to observe and record the flow behavior.

- Observe the material – Note whether the blockage involves sticky fines, large lumps, or cohesive mixtures.

- Inspect geometry and liners – Look for worn or warped liners, rough surfaces, or shallow slopes where velocity drops.

- Review operations – Check if feed rates, ore characteristics, or maintenance practices have shifted over time.

- Model and measure – Use flow property testing to quantify cohesion and wall friction, and apply Discrete Element Method (DEM) simulation to analyze where flow slows, impacts, or accumulates.

- Bring in an expert – have Jenike & Johanson perform a site assessment to pinpoint the problem and develop a pathway to a solution.

Systematic observation and data-based analysis replace trial and error methods that can lead to repeated modifications without addressing the real cause of the hang-up. By connecting field symptoms with measurable material properties, engineers can pinpoint the true cause of flow issues before making costly adjustments.

Minimizing Hang-Ups in Transfer Chutes

Chutes are often the first place where flow problems appear. As material travels through them, even small changes in slope, curvature, or liner condition can form zones where ore slows, accumulates, and eventually stops moving.

How hang-ups form

- When ore hits a corner, ledge, or shallow slope, it decelerates and begins to pile up.

- Sticky or cohesive material can adhere to chute walls, reducing the effective opening and triggering a blockage.

- Over time, rough or worn liners increase friction, intensifying the slowdown and accumulation that lead to hang-ups. Additionally, worn liners can change the trajectory of the flow as their thickness has altered and, therefore, changes the flow path.

- High-impact drops generate dust and fines that pack together and adhere to walls.

How to minimize them

- Refine geometry – Replace sharp corners with curved or chamfered transitions, and increase slope angles where feasible to maintain flow velocity.

- Use smoother surfaces – Install low-friction liners and eliminate weld lips or protrusions that interrupt movement. During a liner change, the wear rate of the liner must be considered. Abrasive wear tests can be run to see if the liner will wear faster or last longer than the existing liner.

- Control impact – Adjust drop heights and impact angles to minimize material bounce and fragmentation.

- Maintain proactively – Schedule regular cleaning and replace liners before they degrade. When changing liners, ensure the new liners do not form an upward facing ledge that can cause buildup. Vibrators or air cannons should only be considered after a site and material flow assessment is performed to see if they are a reliable solution for sticky ores prone to buildup.

- Align trajectories- Match belt speeds and angles so material lands centrally on the next conveyor, and use hood-and-spoon or curved deflectors to keep the trajectory controlled.

- Monitor regularly- Inspect for side buildup and clean early, as small accumulations are far easier to manage than full blockages.

Properly shaped and protected chutes help ore accelerate smoothly, reducing stoppages and improving liner life.

Transforming Ore Flow Troubleshooting into Reliable Operation

Hang-ups often indicate a mismatch between material behavior and the equipment designed to handle it. When engineers recognize how ore interacts with chute and transfer geometry, they can address emerging issues before they affect production. Jenike & Johanson helps operations identify such mismatches and implement solutions that restore reliable flow. Through ore flow troubleshooting, laboratory flow testing, and DEM-based design, our engineers diagnose the root causes of hang-ups and develop practical, data-driven corrective measures. Ore should move as predictably as the equipment that carries it, and with science-based design and analysis from Jenike & Johanson, it does. Speak with our experts to discuss your flow challenges and determine the most effective path to consistent operation.