Powder Show

Powder Show

Transfer Chutes

Gravity reclaim stockpiles are an effective way to store large quantities of material.

Transfer chutes are used in many industries to facilitate bulk material transfer from one conveyor belt to another or for redirecting flow from a delivery point (e.g., feeder, screw conveyor) into a process or equipment (e.g., centrifuge, dryer, screener, etc.). Though the transfer chute itself may appear to be only a small or low-cost part of the equipment train, it can easily become a costly bottleneck and maintenance nightmare due to:

- Plugging or buildup

- Abrasive wear of chute or liner

- Spillage and dust emission

- Belt off-tracking

- Segregation

- Particle attrition (breakage)

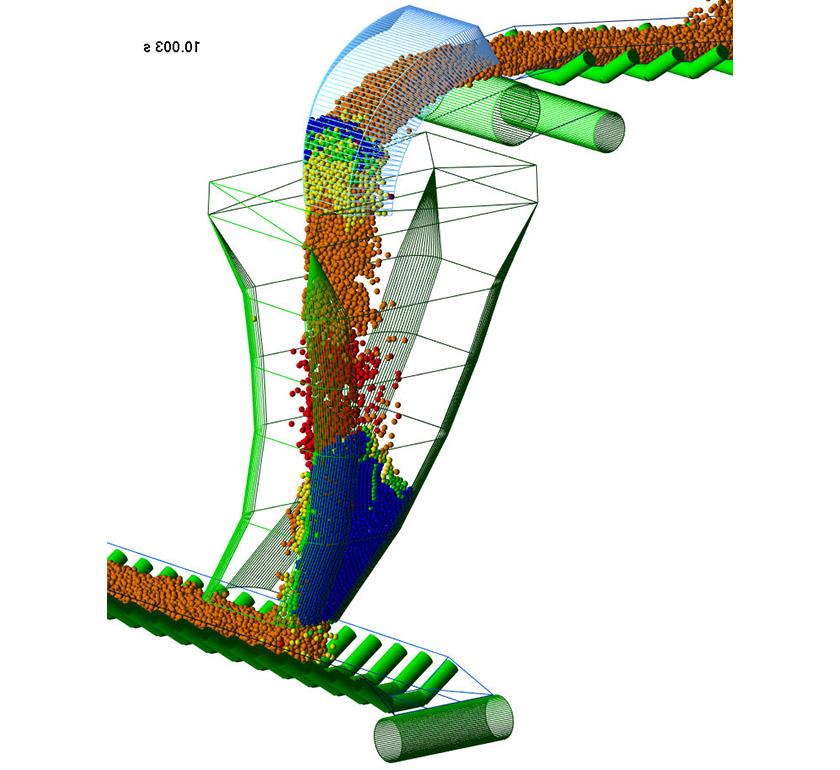

Jenike & Johanson specializes in evaluating your chute applications, whether troubleshooting complex problems or developing new chute designs. Review our solution approach below, which is based on proven bulk material theories, cutting-edge proprietary discrete element modeling (DEM) analyses, material flow properties, and decades of experience designing and implementing transfer chutes that work from the start and operate trouble-free for years.

Iron ore transfer chute hood.

DEM analysis of a chute stream stagnation.

Chute wear