Manufacturers of asphalt roofing shingles often use fine, hot limestone as filler with liquid asphalt. In order to maintain uniform mix viscosity and temperature, flow of limestone into the batch mixer must be controlled and reliable.

One manufacturer tried various surge bin designs for fine limestone which were unacceptable. Vibrating bin dischargers were most unsatisfactory since the discharge rate varied from no flow to uncontrolled flow, or flooding. Depending on the flow properties of material to be handled and operating conditions, gravity discharge is not always the most practical solution when designing bins, silos, and hoppers for handling bulk solids. An alternative design considered for the hot, fine limestone involved fluidized handling.

The Solution

Example 1:

After considering the material flow properties and handling conditions, Jenike & Johanson corrected these problems by designing mass flow bins with mass flow screw feeders. This approach resulted in reliable flow at the required range of discharge rates.

Example 2:

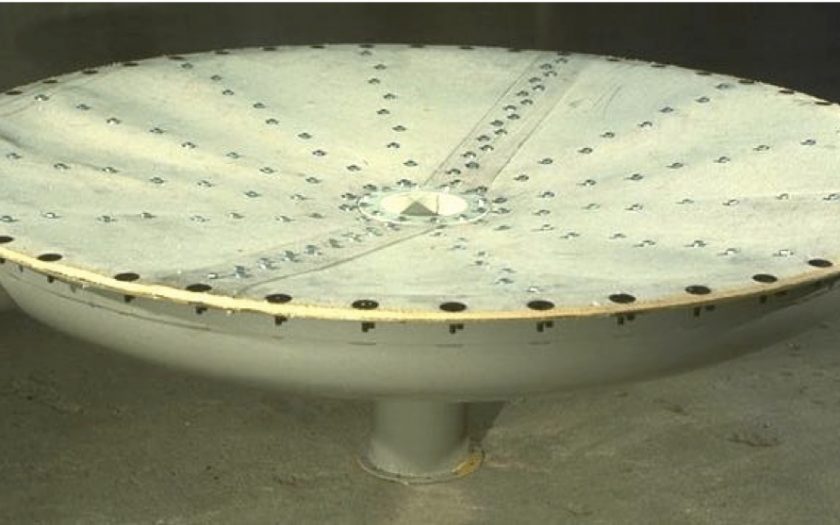

Jenike & Johanson designed, fabricated, and supplied a fluidized bin. Fluidization is accomplished through a 3 ft. diameter twin permeable membrane, the top portion of which is made from KEVLAR® because of high operating temperatures. Discharge is controlled by an existing rotary valve and weigh belt.

The Result

Since the bin was installed, several years ago, it has worked extremely well, providing reliable, controlled discharge at rates in excess of 20 tons/hr.