Waste feedstocks are inherently variable. Their moisture content, particle size, bulk density, and composition change from one batch to the next. These fluctuations determine whether material moves smoothly through handling systems or stalls midstream. When variability is not characterized and addressed, materials can arch, segregate, or stop flowing, leading to process inefficiencies. The key to preventing such problems lies in aligning waste feedstock variability with the principles of material flow science. Connecting the two transforms inconsistent materials into reliably handled solids and enables continuous, predictable performance across waste-to-energy, recycling, and biomass conversion systems.

Characterizing Waste Feedstock Variability

Behind every handling challenge lies a set of material traits, such as moisture content, particle size, bulk density, and composition, that define how waste feedstocks behave in real systems. No two deliveries of biomass or municipal solid waste are identical, and even small differences can dramatically alter how a material compacts, discharges, and consolidates during storage or feeding.

Together, the characteristics of waste feedstocks control the balance between stable flow and blockage within handling systems:

- Moisture content- can rise or fall with weather and storage time, changing how cohesive the material becomes.

- Particle size and shape- affect packing and discharge behavior, influencing flow uniformity.

- Bulk density- governs mass flow and feeder stability, altering throughput consistency.

- Contaminants, fines, and fibrous components- modify friction and compaction, leading to unpredictable handling. Additionally, contaminants containing silica or abrasive materials can increase wear on handling equipment.

Systems designed for an ‘average’ material rarely perform reliably in practice. Managing this variability requires a predictive framework (an envelope of design), one grounded in material flow science.

The Role of Material Flow Science

Material flow science is the discipline that enables engineers to understand and manage how bulk solids move through storage and handling systems. It quantifies how properties such as cohesion, internal friction, wall friction, and compressibility influence flow and discharge behavior.

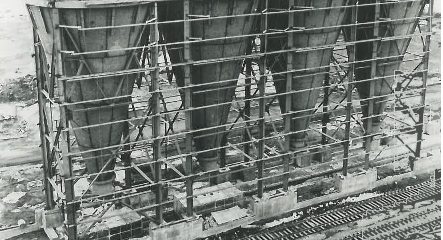

Engineers use controlled laboratory testing to measure these attributes under conditions that replicate real-world handling environments. Tests such as flow function, wall friction, and bulk density evaluations determine how a material will behave as stress, consolidation, and time at rest change. The results define whether a material will achieve mass flow, where all material moves uniformly, or funnel flow, where stagnant zones, segregation, and flow stoppages can develop.

Material flow testing provides the data needed to translate material behavior into design parameters for hoppers, silos, feeders, and conveyors. Flow function data, gathered from either a cohesive strength test or a hopper test for high aspect ratio particles sizes or high-springback particles, determines the minimum outlet size required to prevent arching, wall friction tests establish the hopper wall angle essential for reliable discharge, and compressibility and density tests inform feeder selection and bin geometry. Together, such measurements form the foundation for engineered flow solutions.

By linking waste feedstock variability to measurable flow properties, material flow science allows equipment to be designed for performance across a range of conditions, not just an average case. This scientific approach replaces trial and error with quantifiable insight, ensuring consistent, predictable handling even as waste feedstock properties change.

Aligning Waste Feedstock Variability with Material Flow Science

Alignment begins with recognizing that waste feedstock variation is unavoidable but manageable. Effective integration of material characterization, feedstock conditioning, equipment design, and operational control ensures even highly variable waste streams flow predictably through handling systems.

1. Characterize the Material and Its Variability

Start by measuring how waste feedstock properties change under realistic operating conditions. Key tests assess moisture content, particle size, bulk density, cohesiveness, and wall friction. Laboratory studies simulate compaction, storage time, and humidity to reveal how the material moves from free-flowing to cohesive. The outcome demonstrates the flowability range and limits for reliable handling.

Because biomass and waste feedstock can change regularly, multiple samples require testing to represent and characterize both typical materials and extreme materials that are difficult to handle, generating an envelope of design for a range of feedstock characteristics.

2. Condition and Stabilize the Feedstock

Before storage or feeding, preprocessing helps moderate the extreme variability often found in waste feedstocks. Techniques such as drying, shredding, screening, and blending adjust moisture content, particle size, and density to bring materials within a more manageable range. In some cases, removing problematic fractions or blending batches with complementary properties further improves uniformity. In combination, these steps stabilize the material so its flow behavior remains predictable under operating conditions. Material testing can also contribute to this process by measuring flow properties on different blends, moisture content, and particle size to determine which processing changes will provide the most improvement to flowability, establishing quantitative data that can support a processing change which reduces project risk.

3. Engineer Systems to Accommodate Change

The design of bulk handling and storage systems should be based on measurable data from material flow testing. Hopper geometry, outlet size, and feeder type must correspond to the material’s flow behavior to ensure uniform discharge. Mass-flow hoppers promote consistent movement and prevent arching if paired with the correct screw, belt, and vibratory feeders. Liners or discharge aids can improve reliability for cohesive or fibrous feedstocks when testing shows a benefit, as certain discharge aids may induce overconsolidation, and surge capacity helps absorb short-term fluctuations in feedstock quality. Care should be taken when designing surge capacity as waste feedstock is likely to arch if over consolidated. Engineers can use material flow testing data to understand the maximum consolidation pressure a biomass feedstock can endure before significant arching occurs. This allows the appropriate surge capacity configuration to be designed.

4. Monitor and Adapt During Operation

Waste feedstock properties change during storage and processing, affecting how materials flow. Monitoring bulk density, moisture, and flow rate helps detect shifts early. Automated controls can adjust feeder speed, switch streams, or initiate reconditioning to maintain stable operation as material properties vary.

The Impact of Alignment on Reliability and Efficiency

When waste feedstock variability is managed through material flow science, handling becomes consistent and predictable. Key outcomes include:

- Fewer flow interruptions and blockages

- Stable feed rates across operations

- Lower maintenance and downtime

- Improved overall process efficiency.

Treating variability as a design factor rather than an obstacle can turn a potential problem into a performance advantage, leading to higher reliability, lower maintenance, and improved process performance.

Turning Variability into Reliable Flow

Waste feedstocks and biomass will always vary, but their handling does not have to. Jenike & Johanson’s biomass flow and waste feedstock flow testing services apply material flow science directly to these challenges. Our testing replicates real handling conditions to measure how materials behave and provides the data that translate material behavior into dependable system design. Partner with Jenike & Johanson to characterize your waste feedstock and apply proven material flow science for consistent, reliable handling performance.