Powder flow failures often stem from how particle properties respond to moisture, air exposure, and contact with process surfaces. These interactions directly influence powder flowability and determine how material moves through a system. The result can be blocked hoppers, uneven dosing, caking, clumping, or stagnation in storage. Such problems are not isolated faults but symptoms of materials behaving outside the conditions they need. Addressing them requires targeted techniques that improve flow, reduce variability, and keep systems running as designed.

Addressing the Root Causes of Poor Powder Flowability

Improving powder flowability starts with understanding what drives failures. Factors like particle cohesion, moisture sensitivity, and equipment mismatch all contribute to issues like caking, clumping, and inconsistent discharge. The techniques that follow are practical responses to these challenges. They are each focused on restoring control and reliability to powder handling processes.

Particle Design and Structure

Adjusting particle size and shape can improve how powders behave in motion and reduce the tendency for flow interruptions.

Granulation

How it works

Granulation converts fine, loose powder into larger, more uniform granules using either high-pressure compaction (dry granulation) or the addition of a liquid binder followed by drying (wet granulation).

Issues mitigated

- Caking caused by compaction during storage

- Segregation of blended components due to particle size differences

- Excessive dust that interferes with flow and handling

How it enhances powder flowability

With increased mass and a lower tendency to stick together, granules handle stress more effectively and resist bonding under pressure. Their uniform structure keeps powder moving consistently through equipment and supports precise, repeatable dosing operations.

Particle Shape Optimization

How it works

Particle shape is optimized through techniques like spray drying or spheronization, which produce smooth, rounded forms. These shapes reduce friction and mechanical interlocking, allowing powders to flow more easily through equipment and minimizing the risk of bridging or uneven discharge.

Issues mitigated

- Bridging where angular particles lock together

- Uneven discharge due to particles dragging on surfaces

- Product separation caused by erratic movement during flow

How it enhances powder flowability

By minimizing contact points and reducing drag, rounded particles move more easily through hoppers and conveying systems. Consistent movement within the system enables accurate feeding, reliable dosing, and uniform mixing downstream.

Surface Treatments and Additives

Surface treatments and additives are used to reduce stickiness and limit moisture sensitivity at the particle level.

Flow Aids

How it works

Flow aids are fine, inert powders like silica or talc that are mixed into the bulk material. They coat each particle with a thin barrier that reduces friction and prevents them from sticking together.

Issues mitigated

- Cohesion that causes ratholing or clumping

- Electrostatic charge leading to sticking on equipment

- Irregular dosing from poor flow through feeders

How it enhances powder flowability

The coated particles separate more easily and move with less resistance, making flow more stable in both gravity-fed and pneumatic systems.

Anti-Caking Agents

How it works

Anti-caking agents are materials added to absorb excess moisture and prevent powders from bonding. Common examples include tricalcium phosphate and magnesium carbonate, which sit between particles to stop them from fusing under humid conditions.

Issues mitigated

- Caking during storage or shipping

- Formation of hard lumps inside bags or bins

- Product spoilage from trapped moisture

How it enhances powder flowability

Moisture-absorbing additives prevent particle bonding and help powders remain loose and stable, even under fluctuating environmental conditions.

Environmental Conditioning

Managing temperature and humidity is essential for preserving powder flowability throughout handling and storage.

Humidity Control

How it works

Humidity is controlled using desiccant dryers, HVAC systems, or sealed packaging environments that limit the air’s moisture content. Maintaining dry conditions is especially important for powders that absorb water from the atmosphere.

Issues mitigated

- Surface wetting that causes clumping or cohesion

- Moisture-driven degradation or spoilage

- Variability in flow due to moisture-related property changes

How it enhances powder flowability

Stable humidity helps powders retain their engineered structure and performance. It reduces handling variability and supports uninterrupted flow during discharge or feeding.

Temperature Stabilization

How it works

Temperature control systems, including insulated storage, climate-controlled rooms, or heating elements, are used to keep powder environments consistent and avoid condensation caused by rapid temperature changes.

Issues mitigated

- Condensation inside containers leading to caking

- Thermal cycling that changes particle density or structure

- Localized clumps near cold surfaces

How it enhances powder flowability

Stable temperatures prevent the formation of moisture bridges and maintain the physical integrity of the powder, resulting in smoother, more predictable flow.

Equipment and Mechanical Optimization

Effective powder flowability also depends on equipment that supports steady movement and complete discharge.

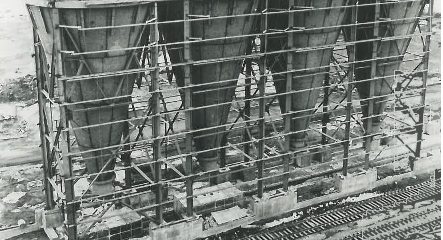

Mass Flow Hopper Design

How it works

Mass flow hoppers are designed so that all material moves together as a unit during discharge. They rely on steep wall angles and smooth contact surfaces to ensure even flow across the full cross-section.

Issues mitigated

- Material left behind in bins

- Inconsistent discharge rates

- Sifting segregation during flow

How it enhances powder flowability

Uniform flow minimizes buildup and ensures every part of the batch flows evenly. This helps maintain blend homogeneity and supports continuous operation.

Bringing Powder Flowability Under Control

The challenges of powder flowability often arise from the combined effects of material properties, environmental conditions, and equipment design. Managing issues like caking, clumping, and uneven discharge calls for a strategy informed by testing and real-world insight. Jenike & Johanson work with clients to identify the causes of poor flow and apply targeted solutions that enhance consistency, improve efficiency, and support long-term system performance. To learn how our services can help you better powder handling across your operation, connect with our team or explore our capabilities online.