Handling dry bulk materials at scale presents unique challenges for manufacturers striving to achieve their productivity goals efficiently and safely, while maintaining a clean production area and ensuring product quality and integrity. These challenges can be particularly prevalent in sectors such as food processing, pharmaceuticals, and chemical, battery, and cement manufacturing. Pneumatic conveying, which transports powders and granules through pipelines using air or another gas, provides a clean and enclosed method that minimizes dust and reduces contamination risks. It also delivers greater layout flexibility than other modes of transport, making it ideal for complex facility designs. Deciding which pneumatic conveying mode to use in your application, whether that is dilute phase or dense phase, is a key step in designing an effective pneumatic conveying strategy that aligns with operational demands. The selected mode will directly influence flow consistency, equipment longevity, product integrity, and overall system performance.

Dilute Phase: High-Speed, High-Airflow Transport

In dilute phase conveying, a high-velocity, low-pressure airstream suspends and carries bulk materials through the pipeline. Dilute phase systems typically operate at conveying velocities of about 15 – 30 meters per second (around 50 – 100 feet per second), and static pressures below about 1 bar (around 15 pounds per square inch). Additionally, they provide low up-front capital cost, and can convey almost any material.

However, dilute phase systems have limited capacities, typically well below 15 – 30 tonnes per hour, and should be used with caution when handling abrasive materials or in applications where particle breakage or degradation is a concern due to the high velocities and associated kinetic energy involved. Another drawback of dilute phase systems is their high specific energy cost, driven by the substantial airflow required to fully suspend the material. These systems typically operate at solids loading ratios well below 15 kilograms of solids per kilogram of air, meaning large volumes of air are needed to transport relatively small amounts of material. For perspective, one kilogram (2.2 pounds) of air at standard conditions occupies about 800 liters (210 gallons), roughly the volume of four 200-liter (55-gallon) steel drums. This low solids-to-air ratio not only increases energy consumption but also requires large filtration, storage, and blower infrastructure, which can significantly influence system footprint and operating costs.

System Configuration

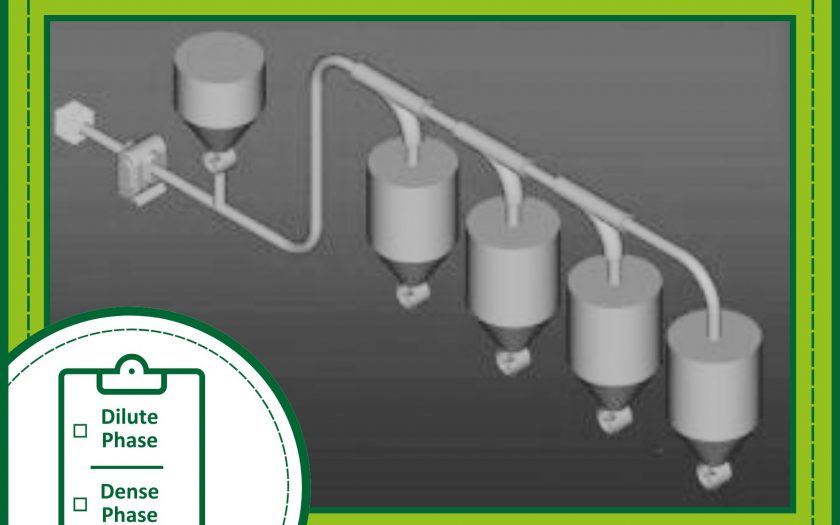

- Positive Pressure: The air mover (i.e., the fan, blower, or compressor) is at the start of the line upstream of the solids feed point(s) and uses positive pressure air to push material through the pipeline. Positive pressure systems are particularly effective for transporting materials in inert gases, over longer distances, at higher capacities, and when delivering material to multiple discharge/receiving points.

- Vacuum Systems: The air mover is at the end of the line downstream of the solids receiving point and generates a negative pressure to pull materials through the pipeline. A vacuum setup offers excellent dust control and is especially useful for shorter conveying distances and environments requiring stringent hygiene standards, and when picking up materials from multiple feed points, for instance in central dust collection systems.

Dense Phase: Low-Velocity, High-Solid Transport

Dense phase pneumatic conveying transports materials that are not fully suspended in the airstream through the pipeline as either concentrated slugs or dunes using high-pressure, low-velocity air. These systems typically operate at feed point air velocities between about 3 – 10 meters per second (around 10 – 35 feet per second), and static pressure between 2 – 10 bar (30 – 150 pounds per square inch). They also provide much higher capacities (typically up to 300 tonnes per hour) compared to dilute phase, and due to their lower velocities, they are much better suited to materials that are highly abrasive and applications where particles are prone to breakage and maintaining product integrity is crucial.

Unfortunately, there are downsides to using dense phase systems. They have much higher up-front costs than dilute phase systems. Additionally, not all materials can be reliably conveyed in dense phase systems, particularly those that are granular or sand-like, as well as materials that are cohesive or sticky. If dense phase is selected for an unsuitable material, this can cause severe production bottlenecks to occur.

System Configuration

- Air Supply: Compressed air at high pressures between 2-10 bar (30-150 pounds per square inch) propels the contents through the pipeline in a dense, controlled flow.

- Flow Control: Precision instruments manage when and how air enters the system, preserving pressure and ensuring steady progress without surges or stalls.

- Feeding Mechanism: Pressure vessels or blow tanks batch-load the contents into the line, enabling the careful control of volume and timing. These systems frequently require additional specialized devices like air knives or dedicated valves to discretize the material as it is fed into the line.

- Conveying Pattern: Depending on system settings and the characteristics of the material, dense phase conveying can move materials as slugs/plugs, typically with coarse, free-flowing materials like plastic pellets, or as slow-moving beds or dunes, which is more common with fine, air-retentive powders like cement, flour, or fly ash.

Determining the Right Pneumatic Conveying Mode

Selecting the right pneumatic conveying mode involves evaluating how every system performs in relation to the characteristics of the bulk material and the needs of the conveying process. A well-matched system ensures consistent flow, protects equipment from wear, and keeps energy and maintenance costs manageable. The following points outline where each pneumatic conveying mode works best and when it might fall short.

1. Material Properties

Fragility

- Dense phase decreases breakage for delicate items like tablets, maintaining product integrity.

- Dilute phase operates at higher speeds and can cause particle degradation, which may impact product quality and increase the risk of dust generation or contamination.

Please note that while dense phase conveying is generally preferred over dilute phase for fragile materials, pneumatic conveying as a whole still causes significantly more particle breakage compared to mechanical systems such as screw or belt conveyors.

Abrasiveness

- Dense phase handles abrasive powders and granules with reduced pipeline wear, helping to lower maintenance costs and extend equipment life.

- Dilute phase may accelerate erosion because of faster particle movement, potentially increasing servicing needs and shortening equipment lifespan.

Cohesiveness and stickiness

- Dense phase suits high-density, non-cohesive materials, offering less abrasive handling and more efficient air usage for heavier loads.

- Dilute phase performs better with cohesive, sticky materials compared to dense phase.

Material suitability

- Dense phase is limited to coarse, permeable or fine, air-retentive materials.

- Dilute phase can convey almost any material.

2. Process Requirements

Conveying Distance

- Dilute phase systems are limited in conveying distance due to their lower static pressures; positive pressure systems can run up to about 300 meters (1000 feet) and vacuum systems are typically limited to a maximum of only about 100 meters (300 ft).

- Dense phase systems are optimal for longer conveying distances (typically up to about 600 meters (2000 feet)) due to the higher static pressures.

Flow Rate

- Dilute phase systems have lower capacities, typically only up to about 15 – 30 tonnes of material per hour for most systems, and have higher specific energy costs for transporting materials thanks to their significant airflow requirements.

- Dense phase provides higher overall system capacities, usually at around 300 tonnes of material per hour, and decreased specific energy costs for moving each tonne of material due to the lower airflow demands.

Batch vs. Continuous

- Dilute phase excels in systems where the continuous, uninterrupted delivery of material is required, like bulk powder delivery in chemical plants and continuous flour transfer in large-scale bakeries.

- Dense phase systems typically operate in batch or semi-batch mode, ensuring their suitability for applications that need controlled or intermittent material delivery. However, they may not work well for processes that require continuous material delivery.

3. System Layout and Complexity

Footprint

- Dilute systems are generally more compact and easier to integrate into existing facilities.

- Dense phase requires extra space and headroom for pressure vessels, additional valving and controls, and compressed air reservoirs.

Multiple infeed points

- Dilute systems generally adapt more readily to incorporating multiple infeed points, since high-cost pressure vessels and high pressure valving are typically not required for feeding solids into the line.

- Dense phase systems tend to be more challenging to configure with multiple solids feed points due to the complexity of their sequencing and the high cost of dense phase feed equipment.

Optimizing Pneumatic Conveying with Jenike & Johanson

An effective pneumatic conveying system does more than move bulk solids. It safeguards product quality, improves operational efficiency, and extends equipment life. Jenike & Johanson offers specialized pneumatic conveying services, including bulk material testing, system modeling, and custom engineering for both dilute and dense phase applications. For expert guidance in choosing the right pneumatic conveying mode for your bulk material, be that dilute or dense phase, contact Jenike & Johanson’s team today.