Open House – Jenike & Johanson Canada is Turning 50!

Open House – Jenike & Johanson Canada is Turning 50!

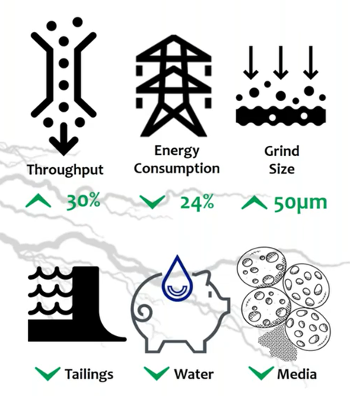

The S.H.O.T. Solution

What can be claimed as the most significant breakthrough in rock fracturing since the HPGR, S.H.O.T. microwave technology uses electric-based, non-mechanical comminution treatment as a pathway to significant energy reduction and enhanced mineral recovery in mineral processing. The fundamental technology partnership between Jenike & Johanson and Crescend combines solids handling and microwave technology expertise to commercialize this exciting technology in the market.

How does it work?

Microwave energy that is typically in the range of 0.3 to 3 kWh/t impacts a flowing ore stream. Differential heating results in fracture at the rock mineral-grain interface, effectively liberating the valuable mineral more efficiently and effectively.

Is it proven?

Both the microwave and bulk solids technologies have been well proven both in the theoretical world and in practice at a 150 tph pilot scale.