ALTA

ALTA

Custom Engineered Equipment Supply

When faced with unique bulk material handling challenges, Jenike & Johanson can provide innovative equipment designs engineered for your challenging applications. In today’s competitive manufacturing environment, bulk solids equipment must work from the start, operate reliably, and have a long service life.

During equipment engineering, we carefully consider the flowability of the bulk material, as determined through flow properties testing. This approach eliminates typical problems seen in bulk material handling designs when the equipment is specified without a complete understanding of a material’s flow behavior or unique characteristics such as abrasiveness, friability (attrition or breakage of particles), or dustiness.

Explore the bulk material testers we can supply.

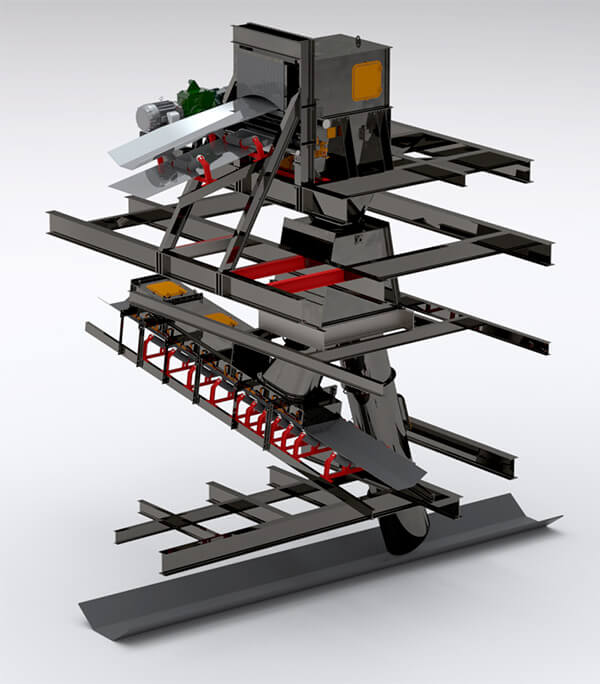

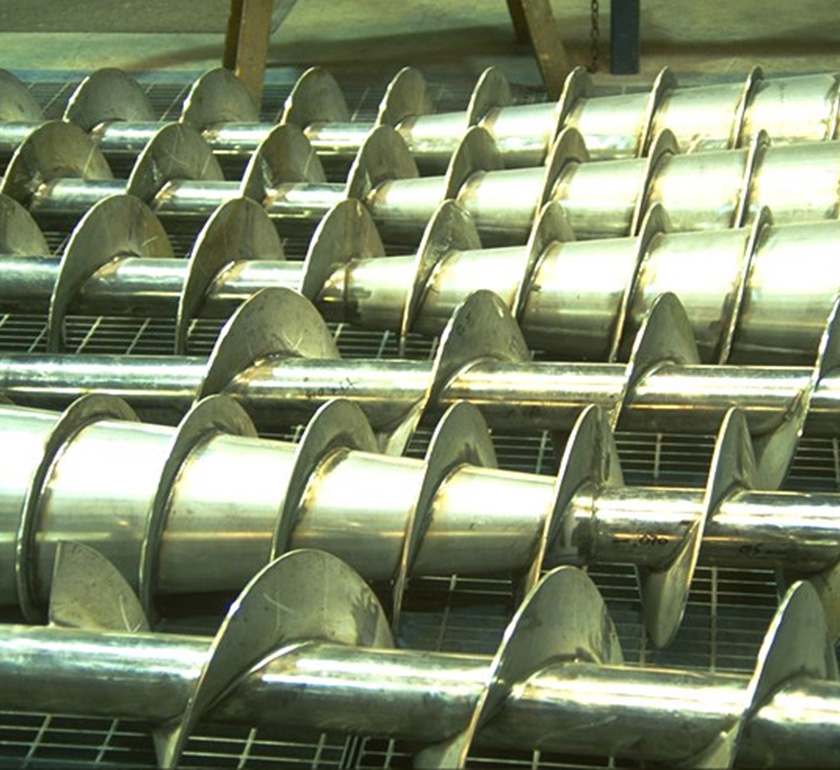

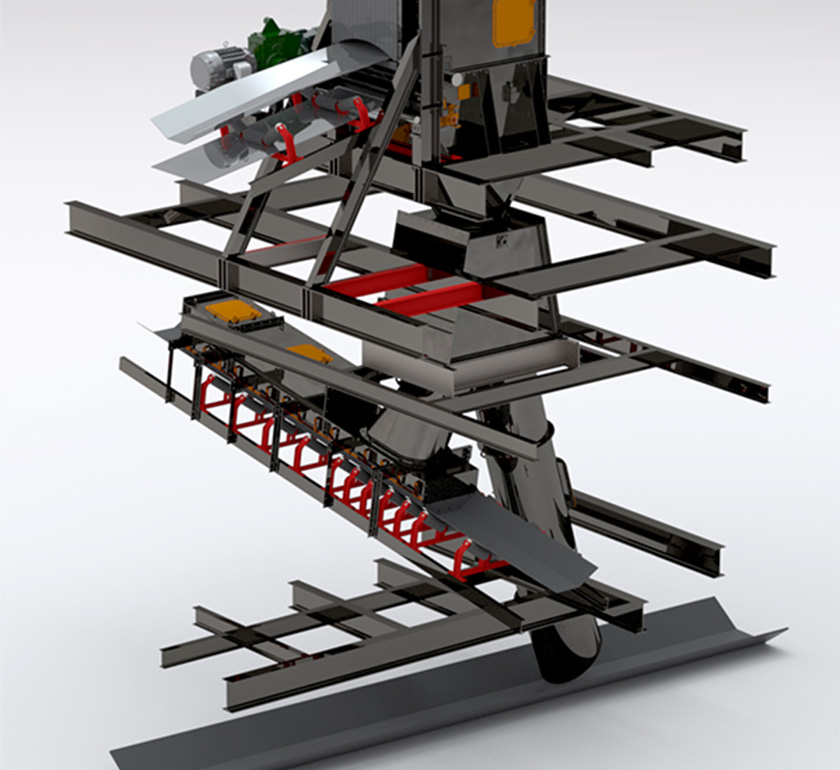

Custom designed mass flow screw feeders.

Custom transfer chute arrangement.