Webinar – Yığın Malzeme Taşımacılığı Bilimine Giriş

Webinar – Yığın Malzeme Taşımacılığı Bilimine Giriş

Overview

Why Segregation Testing?

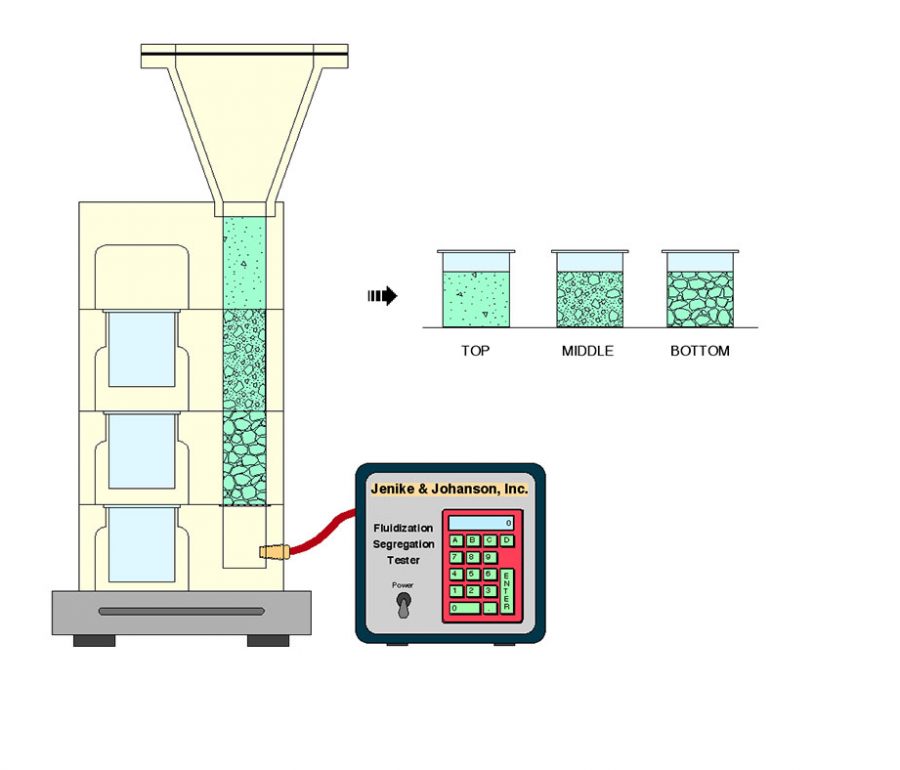

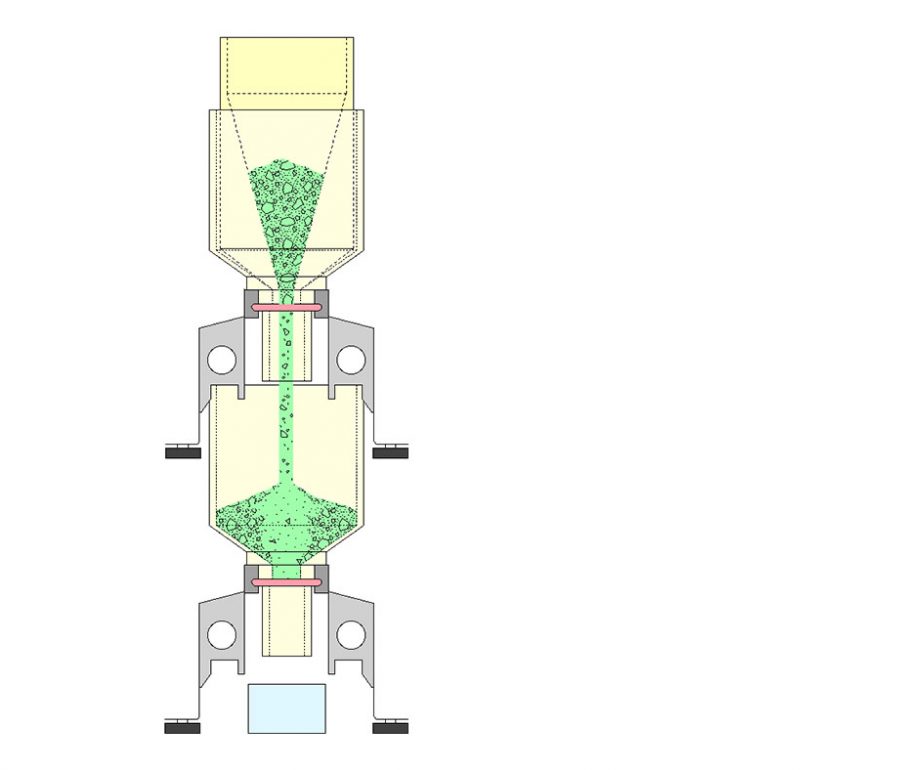

Segregation is a result of particles separating due to differences in their size, shape, or density. Bulk solids can be separated by segregation mechanisms such as sifting, fluidization, and dusting.

The key to avoiding segregation is to determine the segregation behavior of a material and understand how it will transfer through your process in bins, hoppers, chutes, or conveyors. Knowing this behavior will allow equipment designers to either prevent particle segregation or recombine the separated material to maintain product quality.

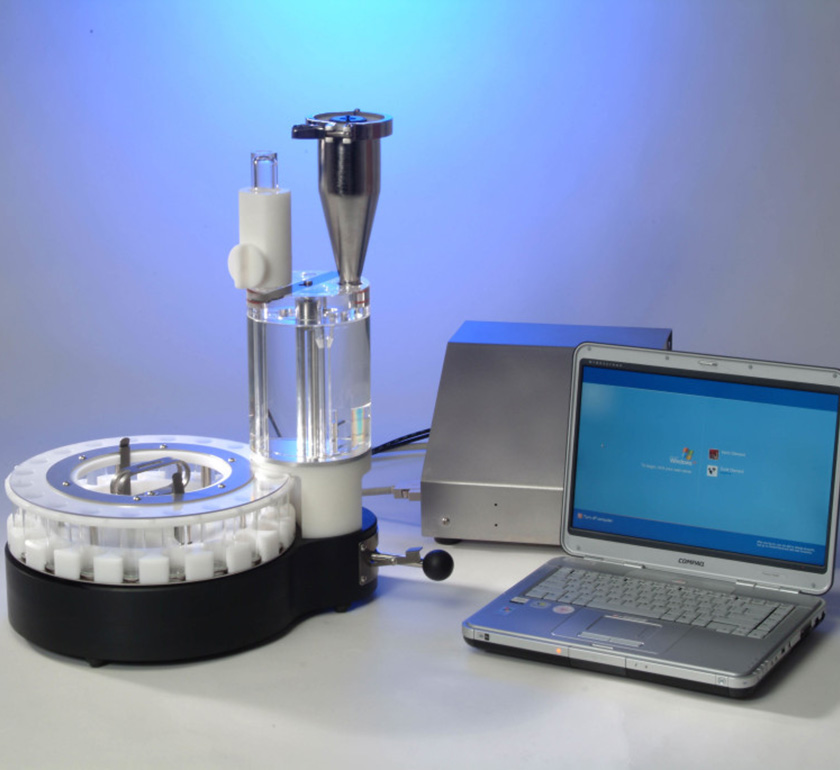

Material sparing fluidization-segregation tester.

Sketch of the fluidization-segregation tester.

Sketch of the sifting segregation tester.