Overview

Why Powder Fluidization Testing?

Fluidization can be a highly effective method for handling a fine bulk material in an aerated or liquid-like condition.

Air or another gas can be used for powder fluidization either in a fully fluidized state or only in a localized manner with small amounts of gas flow.

Fluidization is commonly used with pulverized fuel handling, drying operations, reaction processes, and fine powder hopper discharge systems.

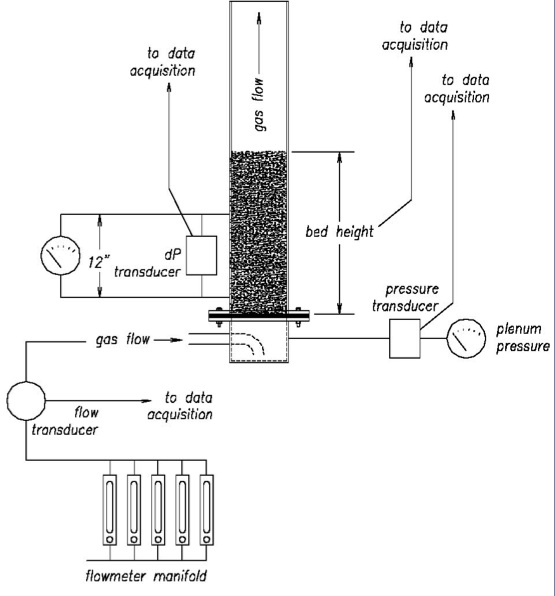

Jenike & Johanson fluidization column apparatus.

Fluidized discharge test.

Fluidized powder in drum.