Open House – Jenike & Johanson Canada is Turning 50!

Open House – Jenike & Johanson Canada is Turning 50!

Overview

Why Abrasive Wear Testing?

Abrasive wear is a result of hard and often angular particles sliding or impacting against a softer surface.

Wear of equipment can be a costly problem when storing and handling abrasive bulk materials such as iron ore, roofing granules, glass, alumina, fly ash, clinker, sand, and copper concentrate. These solids can rapidly erode steel surfaces used in silos, hoppers, transfer chutes, screws or vibratory feeders.

Chute impact zone for abrasive wear.

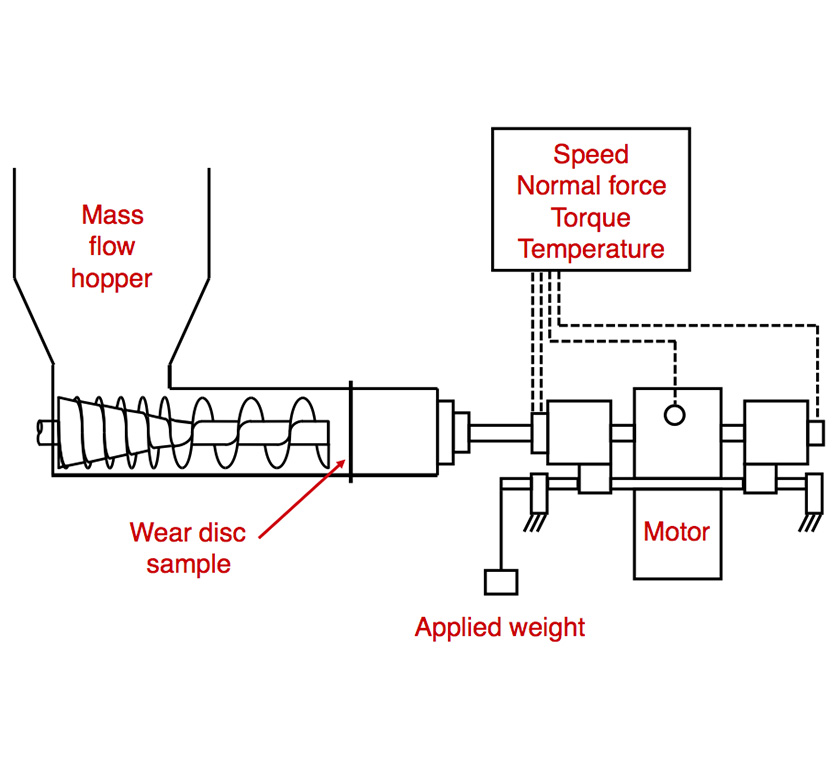

Abrasive wear test setup.

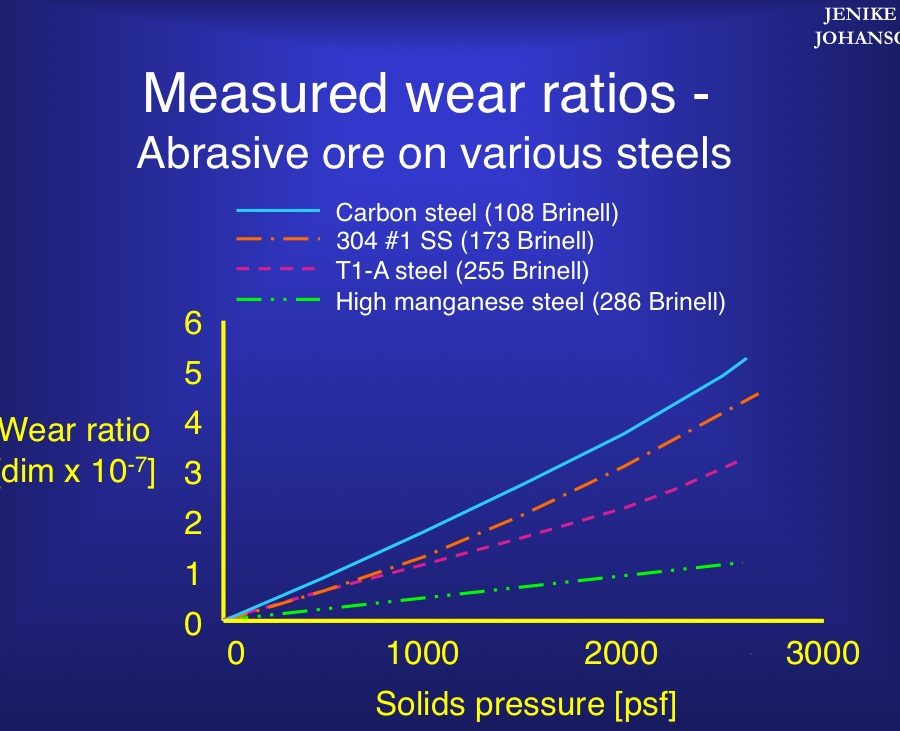

Abrasive wear test results.

Abrasive sintered iron ore

Abrasive and coarse solid rocks.

Wear liners within a hopper.