Open House – Jenike & Johanson Canada is Turning 50!

Open House – Jenike & Johanson Canada is Turning 50!

Conceptual & Functional Engineering of Silos, Feeders, Transfer Chutes, Stockpiles

In today’s competitive environment, just having a standard design for a silo, transfer chute, feeder, or stockpile may not be good enough. In fact, implementing a design that does not carefully consider critical bulk material properties can lead to costs far exceeding the initial capital costs for the equipment.

This is precisely where Jenike & Johanson adds value in your engineering process. Our conceptual and functional engineering designs are developed with thorough consideration of representative powder and bulk solids flow characteristics, and provide the critical information to convey the design intent.

Using our proven bulk material flow theories, cutting-edge analytical models (simulations of material and equipment interactions like discrete element method — DEM — modeling), and decades of experience, we determine the most cost-effective, safe, and practical designs to correct existing material handling problems, as well as to provide reliable equipment designs for new installations.

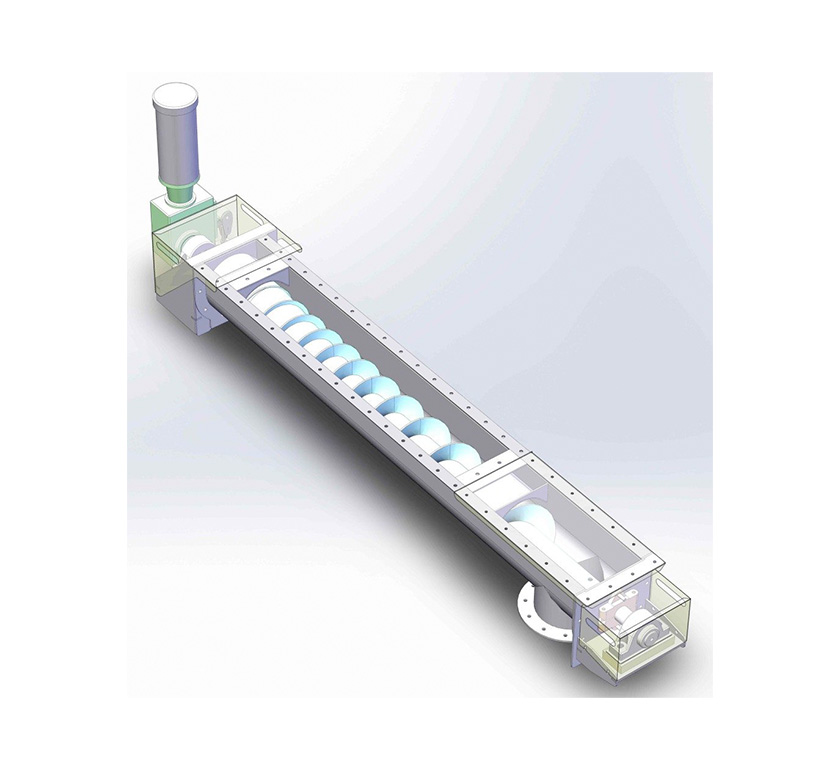

Mass flow screw designed to reliably meter material from a bin or hopper with an elongated outlet.

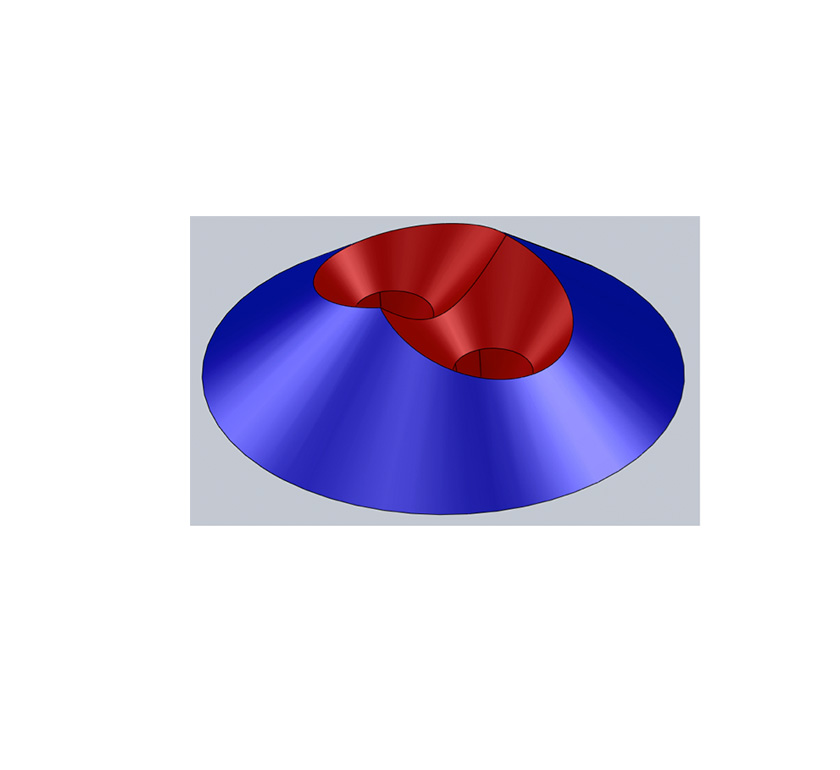

A JPurge™ insert can be carefully designed to promote uniform introduction of process gas across the entire cross section of a reaction vessel.

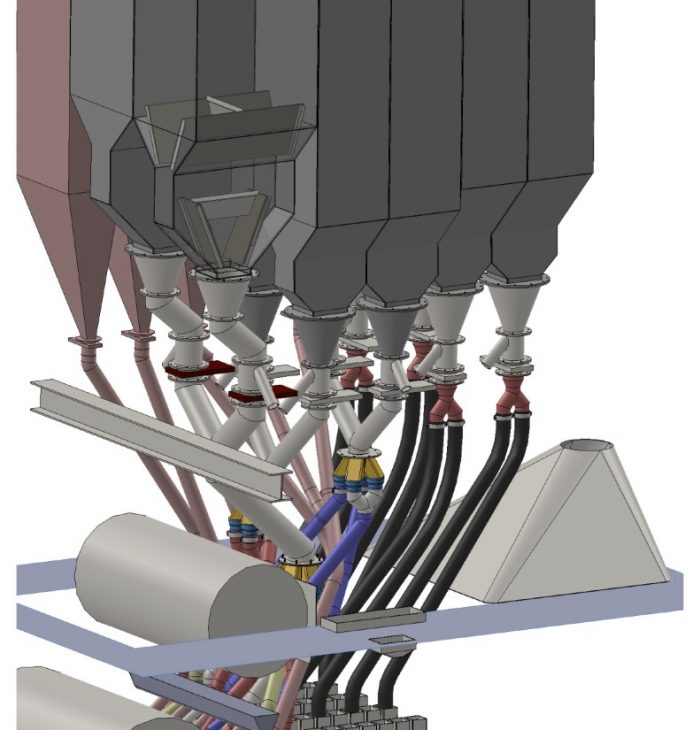

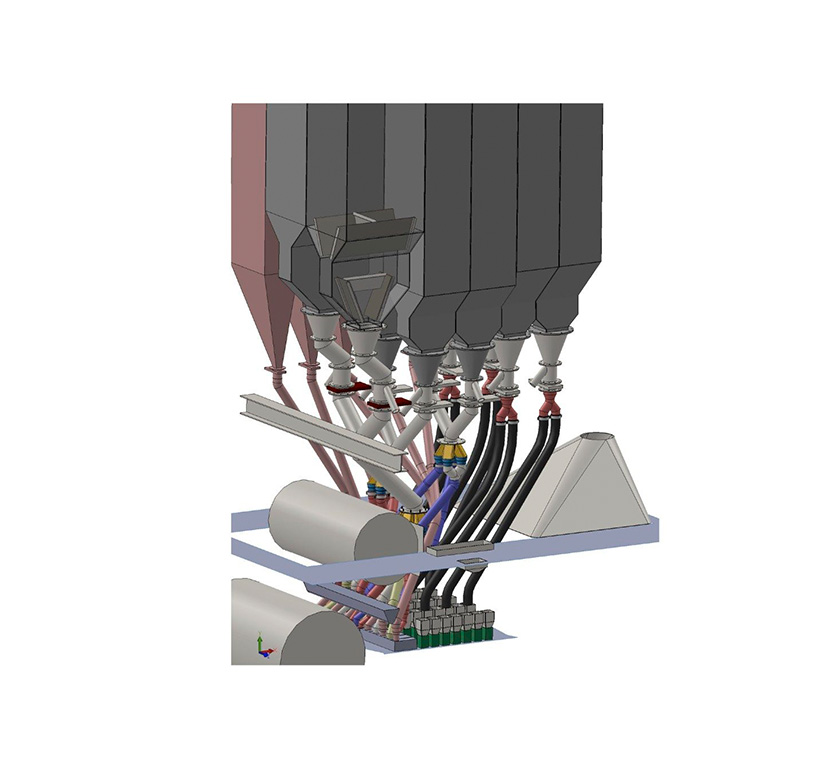

Multi-hopper dispensing system used for precise control of multiple ingredients.

Flow channel analysis can be used to evaluate the active capacity of stockpiles, silos, and feed bins. Accurate calculations for surge capacity are necessary for process and vessel design.