Open House – Jenike & Johanson Canada is Turning 50!

Open House – Jenike & Johanson Canada is Turning 50!

Overview

Stockpiles Overview

Gravity reclaim stockpiles are an effective way to store large quantities of material.

Our gravity stockpile reclaim designs are engineered based on the measured flow properties of the bulk solid being handled, using proven in-house developed methods.

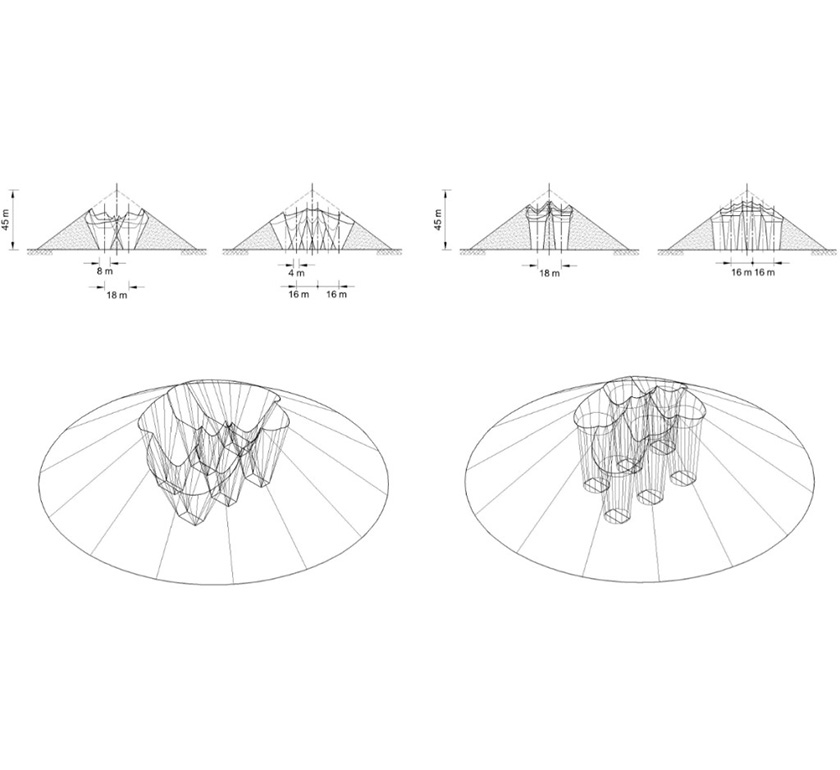

Each of our gravity stockpile reclaim designs is based on an expanded flow principle which incorporates mass flow hopper(s) at the stockpile base. This is critical to provide the required stockpile live capacity and to minimize loads on the stockpile feeder.

Conical stockpile of iron ore.

Stockpile live capacity

Rathole in a stockpile