Webinar – Yığın Malzeme Taşımacılığı Bilimine Giriş

Webinar – Yığın Malzeme Taşımacılığı Bilimine Giriş

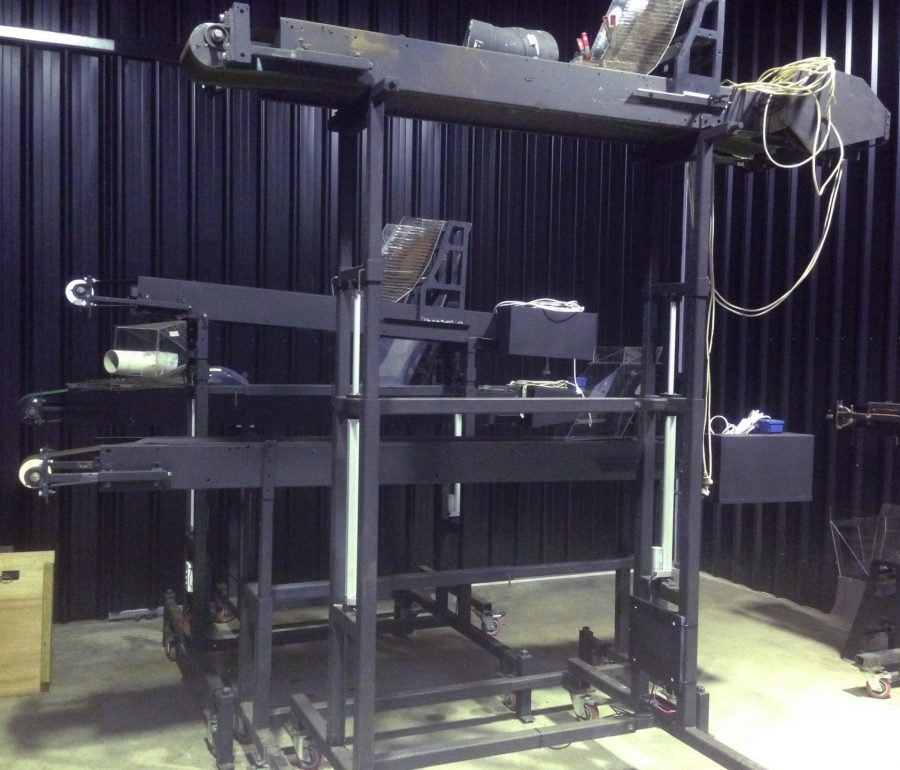

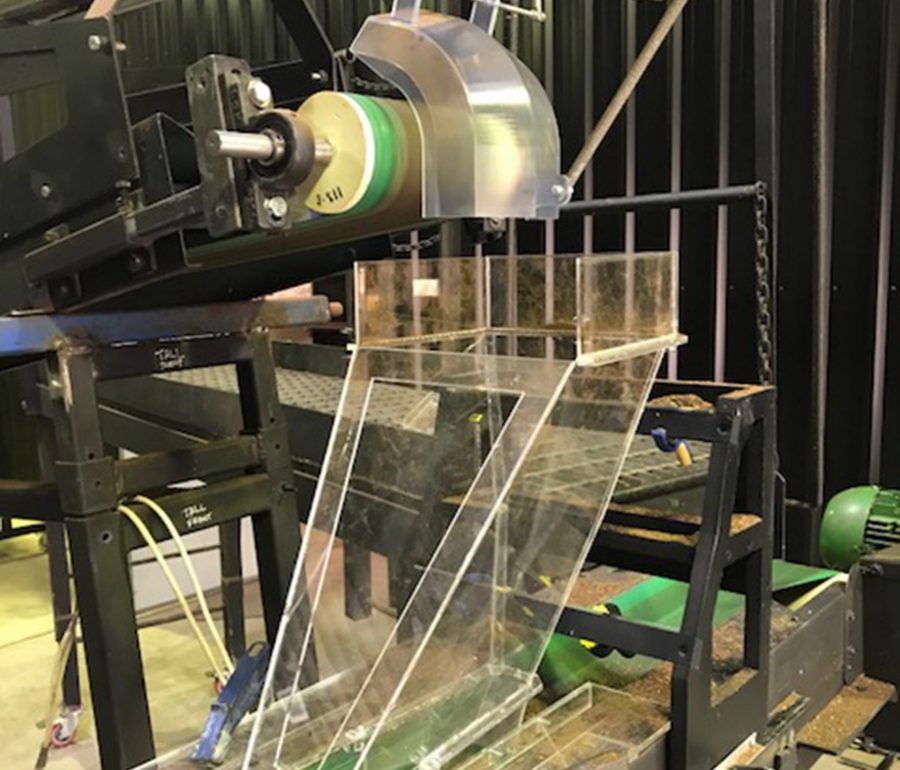

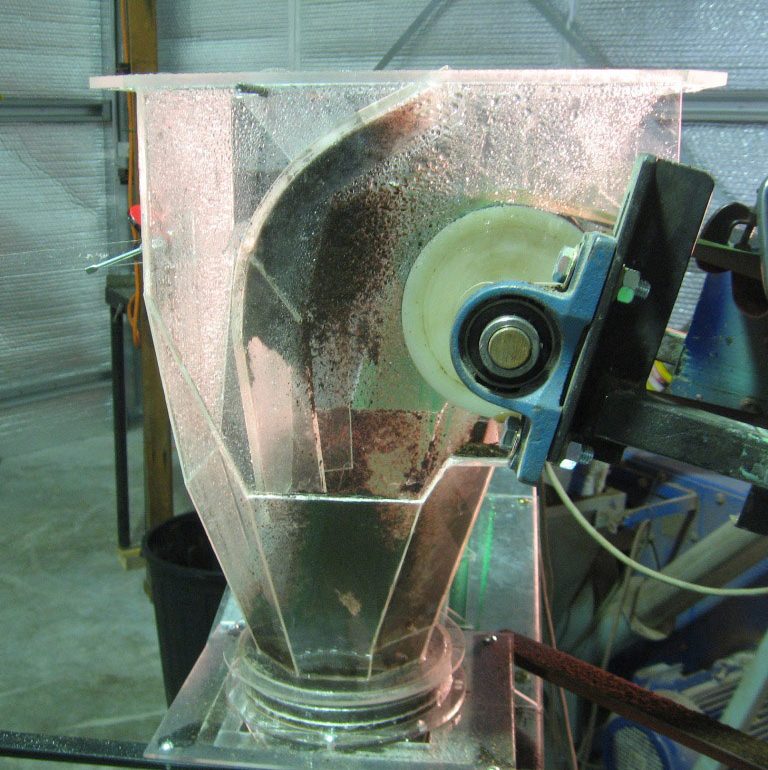

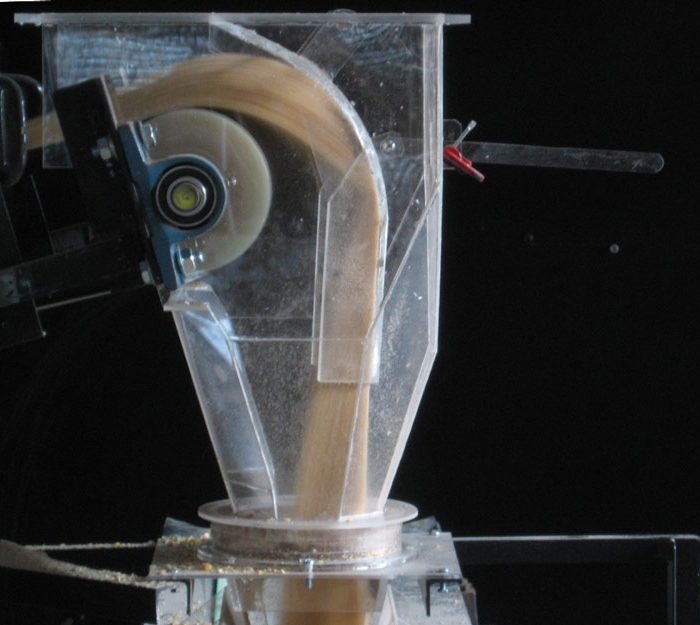

Physical Modeling for Transfer Chutes

Designing reliable conveyor transfer chutes is critical for minimizing downtime, optimizing performance, and controlling costs in industries like mining and material handling. Jenike & Johanson’s new Physical Modeling capabilities offer a revolutionary way to simulate and perfect chute designs with precision and confidence. Using meticulously crafted Perspex models at 1/10 scale and proprietary techniques, our team provides unparalleled accuracy in replicating material flows and belt dynamics. This process allows you to visualize and refine your design, identify potential issues, and eliminate costly mistakes before committing to fabrication. With our state-of-the-art test facility and a proven track record of innovation, we’re redefining how industries approach conveyor transfers, saving you time, money, and operational headaches.