Webinar – Yığın Malzeme Taşımacılığı Bilimine Giriş

Webinar – Yığın Malzeme Taşımacılığı Bilimine Giriş

High-Pressure Feeding and Other Applications

As greater emphasis is being placed on green energy, renewables, and sustainability, biomass consumption is rapidly increasing. Biomass is a general term used to describe a variety of materials including wood chips, pellets, saw dust, milled switch grass, corn stover, etc. From a material storage and handling perspective, these materials can exhibit various handling challenges. Materials such as milled corn stover are very light and often exhibit nesting tendencies that result in discharge issues from hoppers and silos, whereas materials such as woodchips exhibit strong interlocking tendencies. Pellets may undergo attrition and generate dust, which can pose an explosion hazard.

Municipal Solids Waste (MSW) is a feedstock which has flow characteristics that are similar to biomass materials. As such, MSW feedstocks also experience similar flow issues during handling. Whether it is feedstock receiving, stockpile reclaim, silos or feed hoppers, or feed-systems to pressurized reactors, unless properly designed, these systems can experience flow problems such as flow stoppages, limited live storage capacity, feed rate limitation, etc. Similarly, if the feeder and transfer chutes are not designed properly, they can result in flow problems. These problems in the feedstock receiving area can be avoided by properly designing or retrofitting the storage and handling systems.

Feeding biomass and waste feedstocks into a high-pressure, high-temperature environment is an important application in the biofuels industry. Many biofuels conversion technologies involve feeding biomass materials into high-pressure, high-temperature reactors. Delivering feedstock reliably across this pressure barrier is no simple task, especially when the feedstock is difficult to handle materials like biomass and MSW. Our new technology Jen-Zero™ overcomes these challenges.

Logging Truck hauling tree logs.

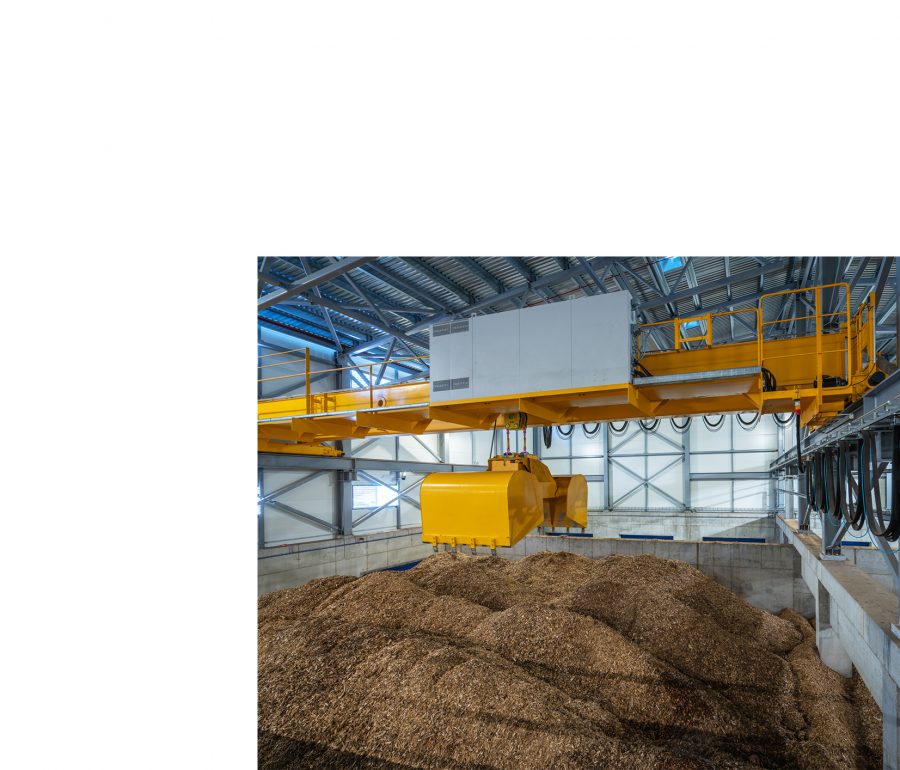

Pile of wood chips in storage.

Woodworking in a sawmill