Open House – Jenike & Johanson Canada is Turning 50!

Open House – Jenike & Johanson Canada is Turning 50!

Overview

Energy & Power

The Energy and Power industries have undergone major changes as a result of economic, environmental, and regulatory requirements.

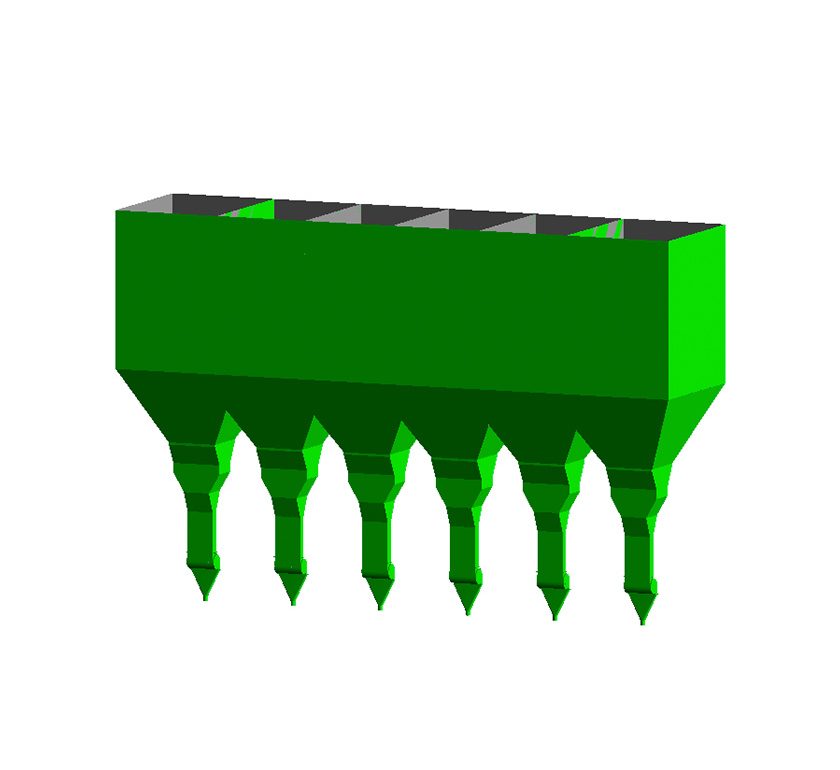

Key changes include co-firing biomass with coal, installing air pollution control (APC) and flue gas desulfurization (FGD) systems, or switching to low-sulfur (e.g., PRB) or waste coals (e.g., gob, culm). Whether feeding a pulverized coal combustor (PCC), a circulating fluidized bed (CFB), or stoker boiler, reliable handling of fuels and their waste streams is critical to energy and power plant operations.

Energy plant

Energy plant