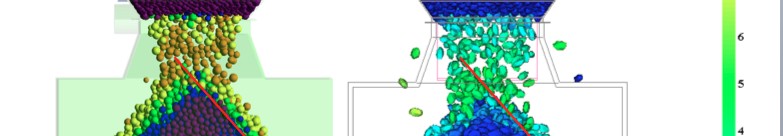

I’m on my journey to Apple’s World Wide Developer’s Conference http://developer.apple.com/WWDC. It sold out in less than two minutes! Guess I’m not the only one that has a high interest in good user interface design. The Cocoa API’s and the Objective-C language have been a powerful combination for Jenike & Johanson to grow and deploy to all engineers, cutting edge tools for design and analysis of bulk solids handling systems including Discrete Element Modeling (DEM). Looking back in time, some of our solutions to the differential equations for solids flow that used to take longer than overnight, are now connected to slider controls which can change a boundary condition, recompute a solution, and display the new solution ten times per second. I can only hope this will be possible with DEM someday. This year my focus is on GPU computing to speed up our DEM models. We have been having a great year working on applying DEM technology to many interesting client problems in mining, steel, power and glass industries. Some movies of this work can be found here.

DEM technology has been around for over 30 years. Andrew Jenike spent the summer at the University of Minnesota in 1976, when I first joined Jenike & Johanson. His question to me was “when would computers be fast enough to work with millions of particles?”. After extrapolating Moore’s law, my reply was in about 30 years. His point was well taken and we continued to develop our continuum models, in conjunction with DEM. Those 30 years have now passed and our extrapolation was on target. GPU computing is ahead of CPU computing power by about 3 years in raw power (affordable teraflops), so hence our interest in GPU computing.