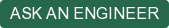

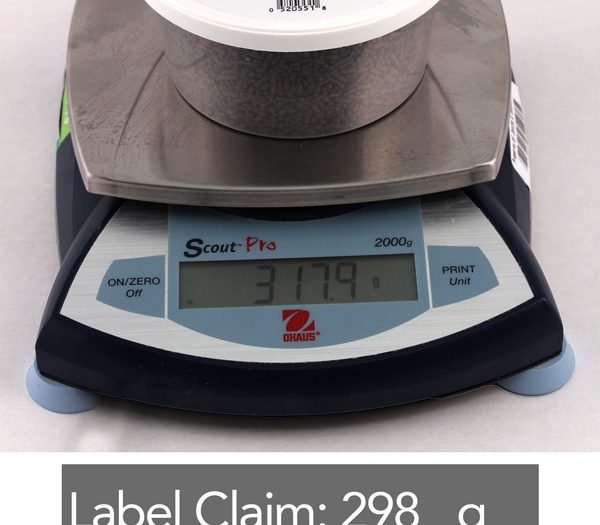

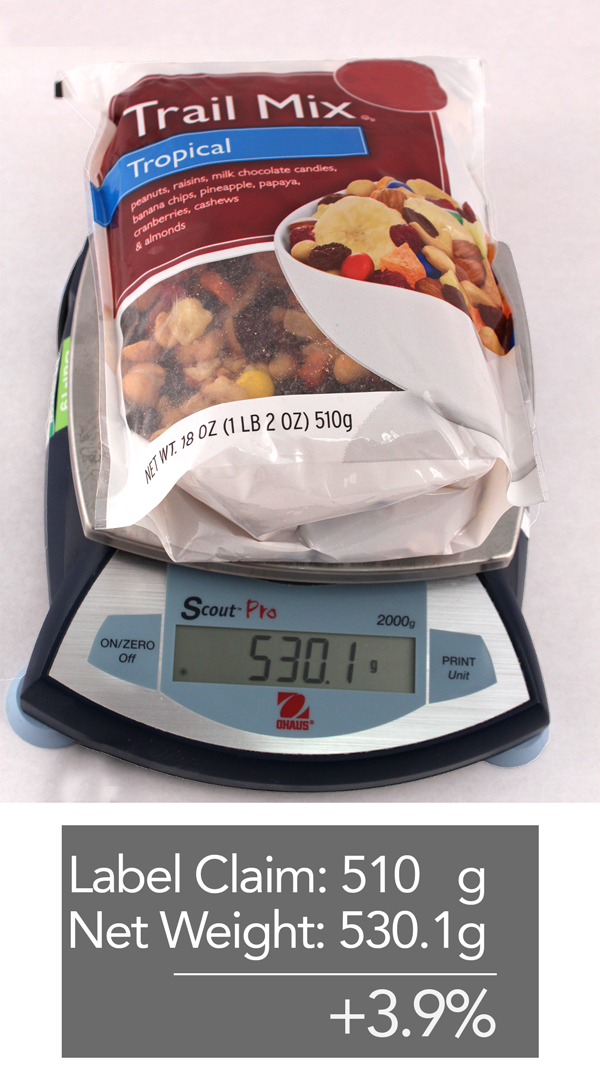

How much of your product can you afford to give away? Any bag or container that is overfilled can hurt your profits. Sometimes, overfilling occurs due to lack of control over the batching process. Other times, overfilling may be preferable to avoid the risk of under filling and ensure FDA labeling requirements are met. No matter the reason, every food and beverage company can cut costs by filling each bag or container more precisely.

How much of your product can you afford to give away? Any bag or container that is overfilled can hurt your profits. Sometimes, overfilling occurs due to lack of control over the batching process. Other times, overfilling may be preferable to avoid the risk of under filling and ensure FDA labeling requirements are met. No matter the reason, every food and beverage company can cut costs by filling each bag or container more precisely.

There are a number of factors that affect the success of a process. Some depend on equipment design; others have to do with the way that a material flows. On one particularly memorable occasion, a plant that was packaging a powdered material was unaware that their substance had a rate limit that needed to be respected to prevent fluidization. They tried to push the material too fast through the process equipment, causing two-phase flow through the bulk filling head and caused segregation container to container. The result was massive amounts of product being rendered unsuitable for consumption and damaged the company’s profits. By identifying the rate limit and adjusting the flow rate to match we were able to mitigate the segregation and two-phase flow within the line and the company was able to keep operating while a long-term solution was developed.

I find it disheartening to see companies that refuse to inquire about their process simply because they believe the solution will be expensive. In reality, though, solutions to giveaway issues are often surprisingly straightforward! Adjusting a hopper angle or changing an outlet size, sometimes by as little as an inch, can save an entire packaging line. The vast majority of packaging and giveaway issues are caused by inadequately designed storage and feeding equipment for the current purpose. Addressing the needs of a bulk material handling/packaging system for thousands of dollars has saved some of our clients millions of dollars in the end.

I find it disheartening to see companies that refuse to inquire about their process simply because they believe the solution will be expensive. In reality, though, solutions to giveaway issues are often surprisingly straightforward! Adjusting a hopper angle or changing an outlet size, sometimes by as little as an inch, can save an entire packaging line. The vast majority of packaging and giveaway issues are caused by inadequately designed storage and feeding equipment for the current purpose. Addressing the needs of a bulk material handling/packaging system for thousands of dollars has saved some of our clients millions of dollars in the end.

As a senior consultant at Jenike & Johanson, I have worked with many process managers and engineers who observe severe giveaway issues but don’t know how to cost-effectively address them. The approach we take for a typical project is straightforward and practical. First, we conduct a process review in the factory. Then, we perform flow property testing on a sample of the material as it is in the process. These steps provide us with the intimate knowledge necessary to identify all root causes and engineer a practical solution for the situation.

Permanent problems cannot be solved with temporary solutions. Addressing the issues may seem like an arduous task, but our systematic approach will enable increased process efficiency & profitability.

If you are experiencing increased or unwanted costs due to product giveaway or line conveyance issues, be sure to discuss your observations with our experts who can provide you with advice and guidance.

Our experienced engineers are available to speak with you via email or phone (+9786493300) whenever you are ready to reach out.