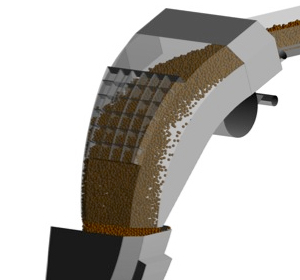

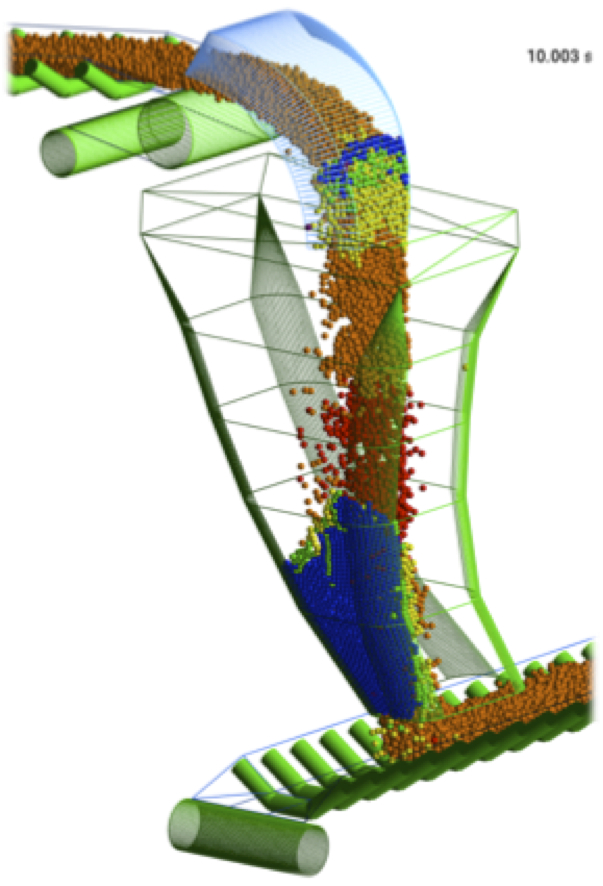

The other night I found myself awoken from a nightmare! I have worked on several jobs recently involving the optimisation of transfer chutes handling iron ore. I have been using Discrete Element Modelling (DEM) to analyse the flow of material through the existing system and then through an optimised one. Topics have ranged from increasing throughput, correct deflector placement through to proper alignment of the feed to the receiving belt.

In my nightmare I found myself hurtling along a belt at some 5 m/s only to be thrown against an impact plate, where I immediately came to an abrupt stop. Following behind me was a belt load of iron material that careened into me pushing me down and off the plate where I proceeded to bounce from one chute sidewall to the other hitting and sometimes sliding along some very hard wear plates. Eventually, I landed on a bunch of iron ore material near the bottom of the chute. “Thank goodness for this plugged material”, I thought as looking out to the front of the chute I could clearly see ground because of the severe off tracking of the belt beneath! I am glad I woke at this point as I am not sure I would have liked the exit.

Jenike & Johanson is often called upon to address and solve issues in transfer chutes like plugging, chute surface wear, dusting, spillage, belt wear and off tracking, lack of throughput and particle attrition. With the drive for ever increasing throughput proper transfer chute design is becoming more and more important. I wish J&J had optimised the transfer chute in my dream as if we had I am sure my downward journey and eventual exit would have been much smoother!