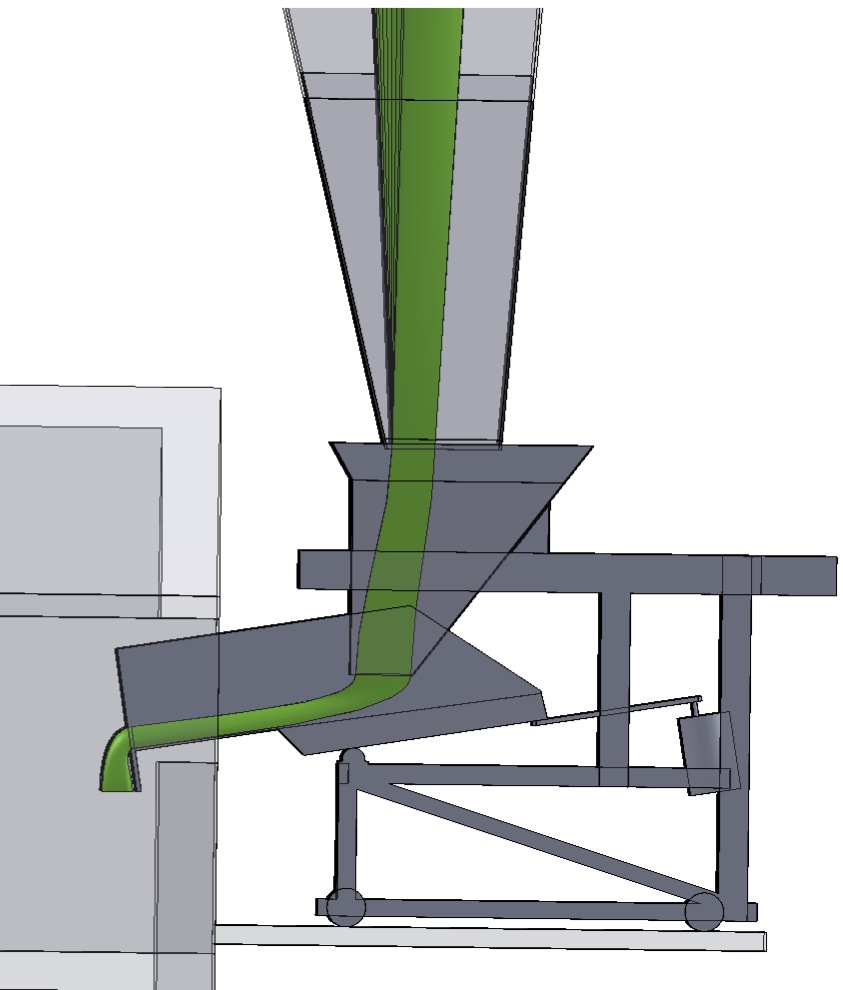

Your furnace feed bin maybe one of the most overlooked pieces of equipment in your glass plant! The bin serves as the main entrance to the value-added portions of your process, and is vital for continuous production and plant operation. Did you know that properly designed, the bin provides these 5 functions?

- Decouples batching and melting activities

- Provides surge capacity in event of interruptions with the batch delivery system

- Maintains your batch homogeneity

- Ensures a consistent feed rate can be maintained to the furnace

- Avoids stagnation and a resulting loss of bin capacity due to batch hardening

Improperly designed feed bins can have devastating effects on your furnace operations and product quality. To develop a reliable design, features must be included to handle your unique mix of materials. Flow property testing of your blended batch allows the hopper section to be designed to facilitate mass flow, which can be extremely helpful in achieving the goals listed above. Proper testing of your material must account for the heat and humidity that the bin experiences due to the incoming material and its proximity to the furnace. Simply testing the material in actual conditions can provide valuable insight, while avoiding the trial and error of not knowing the science behind material flow. Jenike and Johanson has the ability to test your materials up to 2,200ºF (1,200°C) and moisture conditions up to 98% of saturation. If you would like to know more about our testing capabilities, as well as how our evaluation and engineering services can help your process, please contact us.