I am old enough to remember the “new car smell” of the interior of a new automobile. Whenever my parents purchased a new vehicle, they seemed excited when inhaling alkanes and residual styrene monomers. I, on the other hand, was more thrilled that the power windows allowed me to let in fresh air quickly.

I am old enough to remember the “new car smell” of the interior of a new automobile. Whenever my parents purchased a new vehicle, they seemed excited when inhaling alkanes and residual styrene monomers. I, on the other hand, was more thrilled that the power windows allowed me to let in fresh air quickly.

Eventually, consumers, including my parents, realized that inhaling volatile organic compounds was not part of a healthy lifestyle and car manufacturers reacted. To be competitive, suppliers of plastics and other materials had to reduce volatiles to undetectable levels.

The challenge was that removing 99 percent of the impurities was easy. Tackling the final 1 percent was a challenge. In engineering terms, heat transfer was fast; mass transfer was slow. Long residence times were required to remove trace levels of malodorous contaminants.

In response, manufacturers added fluidized bed dryers to their production lines. Unfortunately, although products were now odor-free, the air surrounding the manufacturing site no longer was. Neighbors could only escape the aroma by climbing into their odor-free cars with their power windows closed.

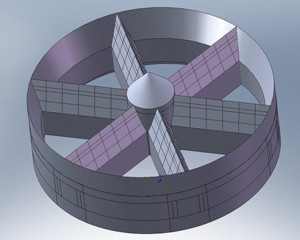

Producers therefore turned to purge columns. Purge columns are silos that have been modified to allow injection of a small amount of sweeping gas to remove volatiles. They have low capital and maintenance costs, afford long residence times, and also provide storage or surge capacity. The volatiles leaving the column can be readily separated using a condenser or membrane or are destroyed by incineration.

Jenike & Johanson uses its [popover image=”/our-services/structural-mechanical-engineering/structural-engineering-purge-column-view/” link_text=”J-Purge™ Gas Delivery System” title=” ” content=”J-Purge™ Gas Delivery System for reliable, uniform resin purging” direction=”right”] technology to allow even distribution of the sweeping gas, designs its columns for mass flow to ensure proper solids flow and the intended residence time, and measures the phase equilibrium to guarantee a driving force for devolatilization throughout the column. In today’s competitive manufacturing environment, purge columns designed by Jenike & Johanson work properly from the start, operate reliably, and have a long service life.

Today’s new cars have many new features, but we sometimes forget what they do not have – the smell of styrene from the car’s upholstery and dashboard.