Caking of powders or granular bulk solids is a very common problem with consequences that could be devastating for your business. In short, your customer will see your caked material as a poor-quality product, resulting in multiple complaints.

We have posted various blogs regarding this phenomenon, primarily addressing moisture as the process parameter responsible for most of the caking problems. However, in order to solve your caking problem, another parameter that deserves as much attention as the moisture in your product is temperature. So, let’s talk about it.

The temperature of your product during storage could have the following effects:

- If the product is packed at an elevated temperature compared to your ambient conditions (e.g., at the temperature leaving your dryer compared to the warehouse’s ambient temperature), the temperature of the product near the surface of the bag or container will cool down, causing a temperature gradient inside the container. The moisture inside the container (even if very little) will then migrate to the cooler regions causing localized areas of relative high moisture content. The high moisture could be sufficient to initiate the caking of your product.

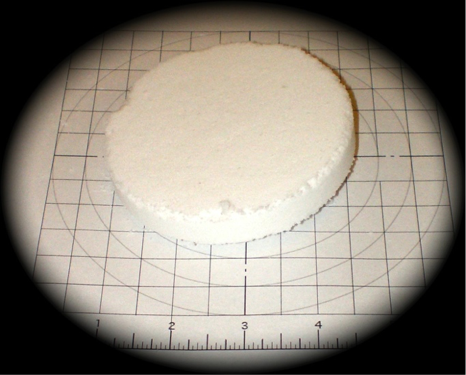

- Your product can get “soft” at elevated temperatures. Depending on the temperature, storage time and intensity of your product’s particles contact (caused by the weight of the particles or by consolidating pressure when the product bags are stored one on top of the other, or at the bottom layer of your container or bulk bag), diffusion of matter forms bridge-like structures at the particle-particle contacts which solidify upon cooling causing severe caking. This phenomenon is called sintering. Examples of this are shown in Figures 1 and 2 illustrating the caking of a fat-rich food stuff and a plastic resin during caking tests in our laboratory.

- If your product contains water-soluble amorphous substances such as powder vegetables, yeast and meat extracts, plant proteins, sprayed-dried dairy powders, sugar syrups, etc., caking due to sintering is also very common. However, in this case your material can be “soft” even at ambient temperature conditions due to a drop in its glass transition temperature caused by its moisture content.

Once more I should remind you that for any product to survive in an environment of global competition, a quality product is imperative. If you are experiencing caking, you can contact us. We can help you solve this problem.

Figure 1: Fat-rich food stuff became sticky and caked when tested at 35° C under consolidating pressures simulating storage in a bulk bag.