Webinar – Yığın Malzeme Taşımacılığı Bilimine Giriş

Webinar – Yığın Malzeme Taşımacılığı Bilimine Giriş

Structural Engineering

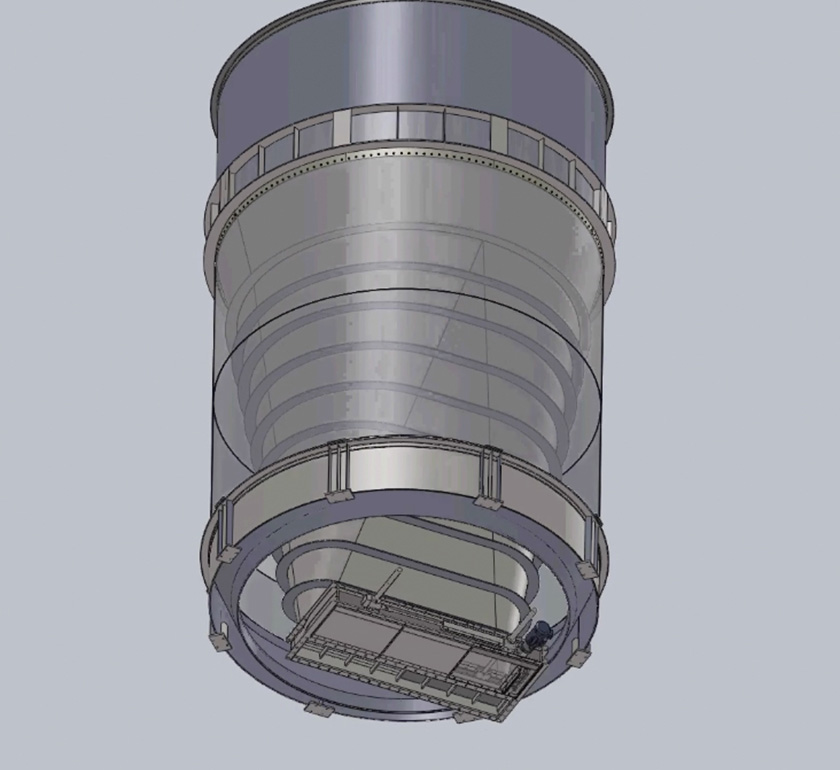

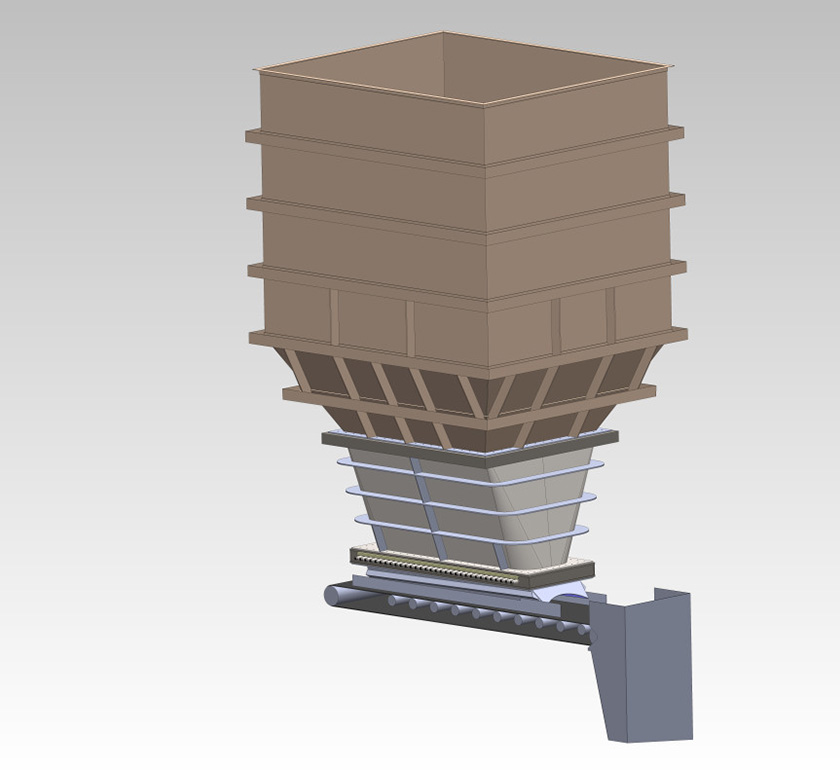

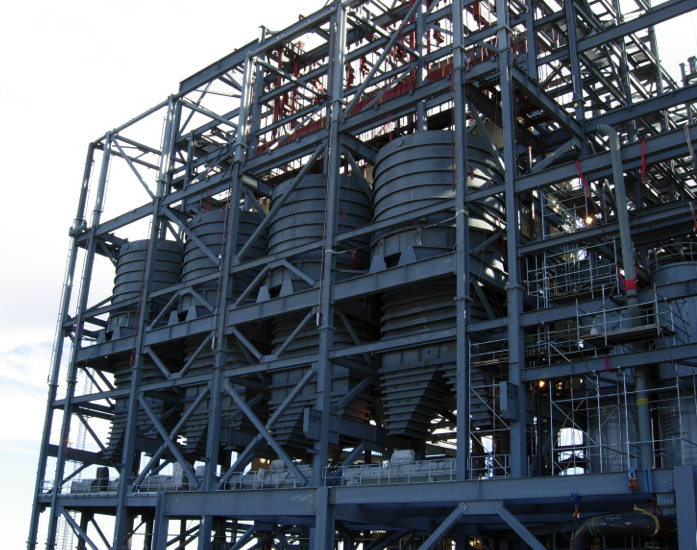

As the world leader in bulk solids storage, handling and processing, Jenike & Johanson has extensive experience in structural engineering of bulk solids storage structures (such as bins, vessels, silos and bunkers) and handling structures. In fact, Dr. Andrew Jenike, the founder of Jenike & Johanson, received his Ph.D. in Structural Engineering from the University of London. Dr. Jenike understood how critical the bulk solids-structure interaction is in a complete engineered bulk material handling solution; therefore, he not only developed and expanded the science of bulk material handling design but also theories and procedures for calculating loads exerted by bulk solids on storage structures.

The Structural Group at Jenike & Johanson has continued and expanded this approach by not only understanding the structural analysis and design of bulk solids storage structures, but also the bulk solids flow behavior and its effect on material-induced loading patterns. Our engineers have extensive project experience in design and analysis of bulk material storage structures used in power, chemical, mining, food, and agricultural industries.