Webinar – Yığın Malzeme Taşımacılığı Bilimine Giriş

Webinar – Yığın Malzeme Taşımacılığı Bilimine Giriş

Examples

Project Examples

- Feeding a sticky, cohesive powder at extremely low rates (1 g/minute)

- Micro-dosing a seasoning mixture uniformly

- Aligning pharmaceutical tablets in a high speed filler

- Filling of ammunition cartridges at high speeds

- Feeding a reactor with biomass with continuous, high accuracy control

- Operating powder fluidization model at high temperature

- Testing of large particle bulk solids (e.g., coal and switch grass)

Physical model of a powder insert.

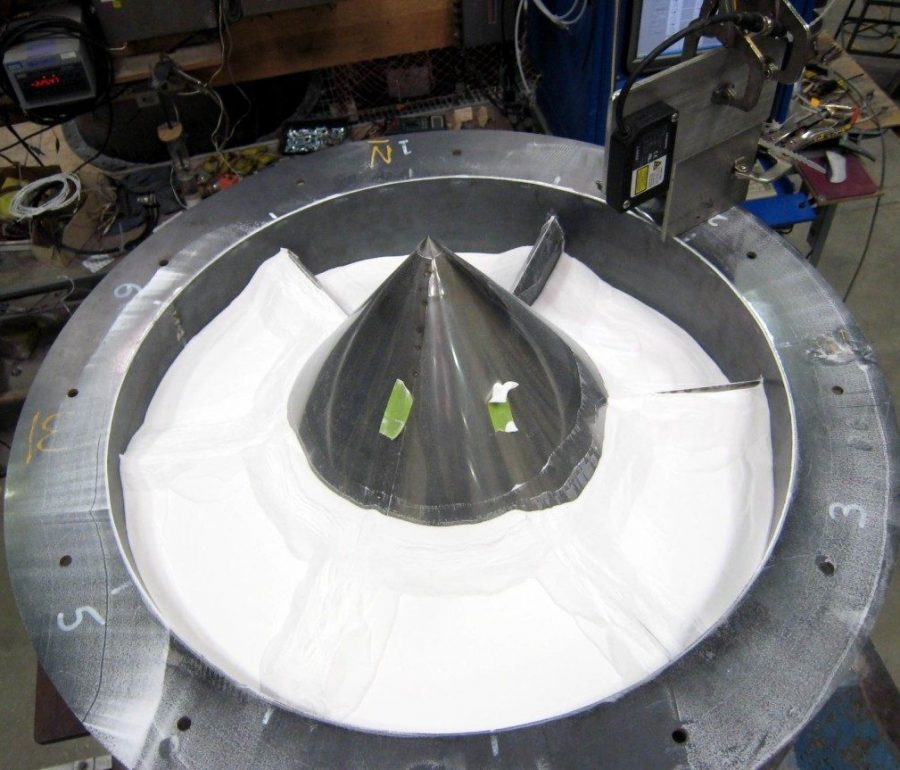

Physical model of a complex hopper

Binsert split model

Physical model of a belt feeder.