Open House – Jenike & Johanson Canada is Turning 50!

Open House – Jenike & Johanson Canada is Turning 50!

Transfer Chutes

Transfer chutes are used in many industries to facilitate bulk material transfer from one conveyor belt to another or for redirecting flow from a delivery point (e.g., feeder, screw conveyor) into a process or equipment (e.g., centrifuge, dryer, screener, etc.). Though the transfer chute itself may appear to be only a small or low-cost part of the equipment train, it can easily become a costly bottleneck and maintenance nightmare due to:

- Plugging or buildup

- Abrasive wear of chute or liner

- Spillage and dust emission

- Belt off-tracking

- Segregation

- Particle attrition (breakage)

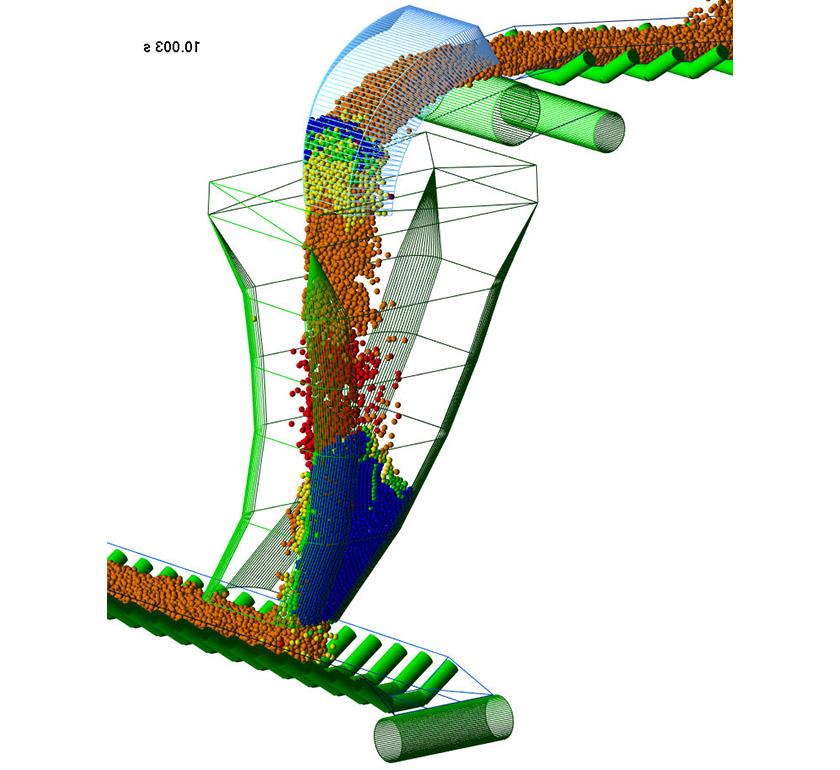

Jenike & Johanson specializes in evaluating your chute applications, whether troubleshooting complex problems or developing new chute designs. Review our solution approach below, which is based on proven bulk material theories, cutting-edge proprietary discrete element modeling (DEM) analyses, material flow properties, and decades of experience designing and implementing transfer chutes that work from the start and operate trouble-free for years.

Iron ore transfer chute hood.

DEM analysis of a chute stream stagnation.

Chute wear