Open House – Jenike & Johanson Canada is Turning 50!

Open House – Jenike & Johanson Canada is Turning 50!

Silos, Bins, & Hoppers Overview

Bulk material storage vessels (e.g., silos, bins, hoppers, elevators, bunkers) are available in a variety of sizes, shapes, and materials of construction. Proper selection of a silo, bin, or hopper requires evaluation of many factors, and in cases where basic material characteristics have been ignored, undesired consequences such as structural failures, caked or segregated material, and erratic discharge have resulted.

Jenike & Johanson engineers excel at thoroughly reviewing your storage needs, measuring critical bulk material flow characteristics, selecting the appropriate hopper discharge pattern, and designing a storage vessel that will operate correctly from the start and provide a long service life.

Review our solution approach and explore how we can help you implement a new storage vessel or retrofit a poorly operating vessel that continues to incur unnecessary costs.

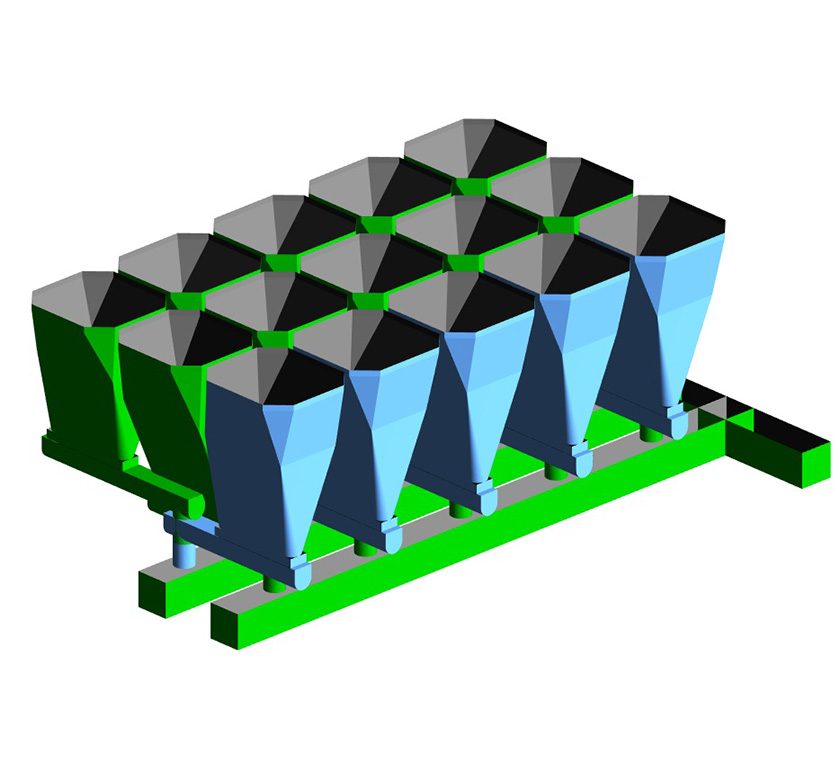

Hoppers within a feed mill.

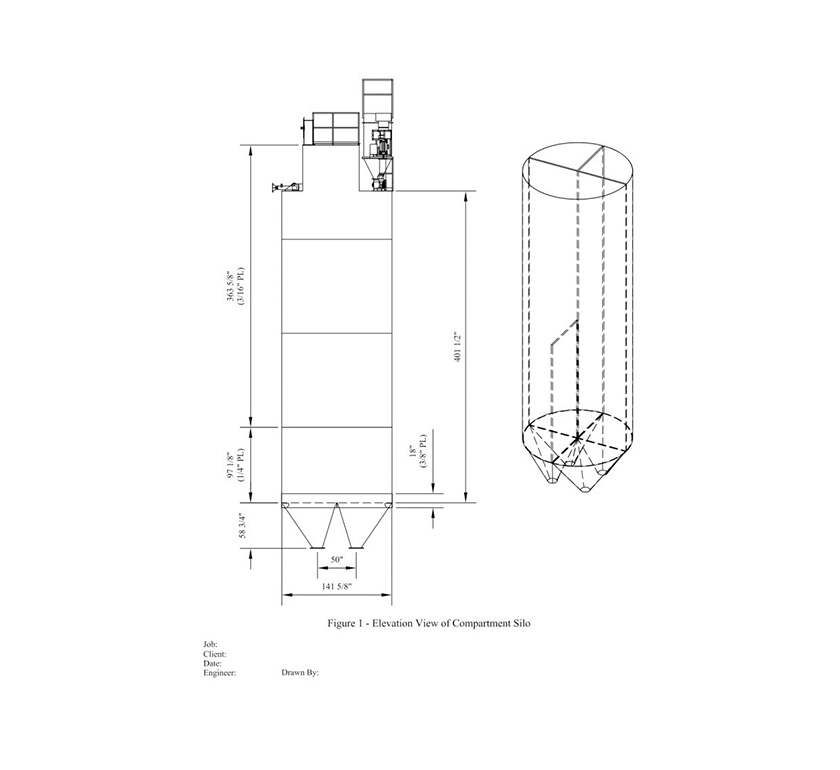

Functional silo design.

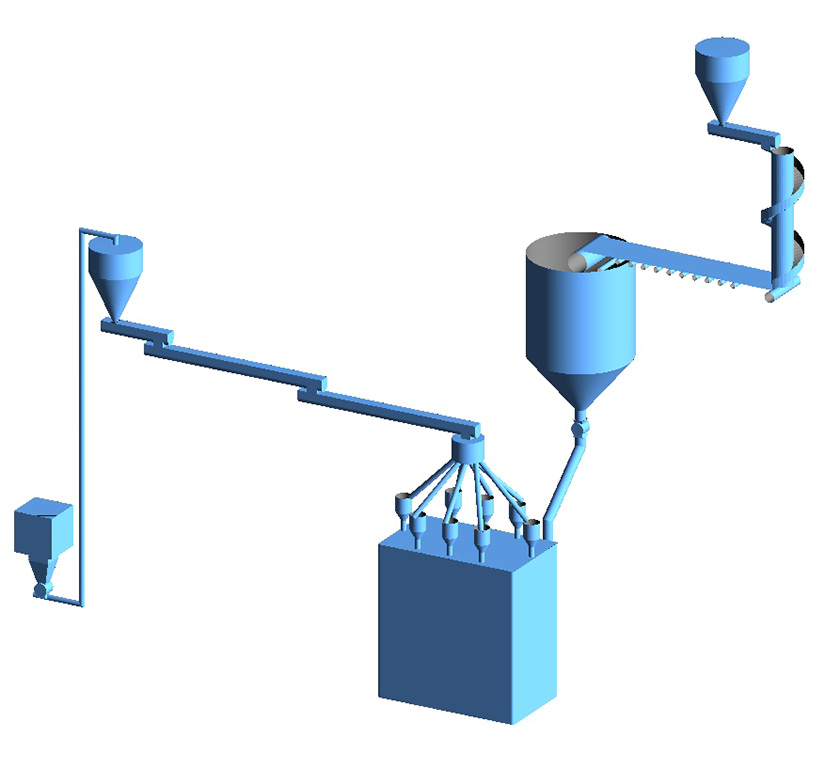

Process design.

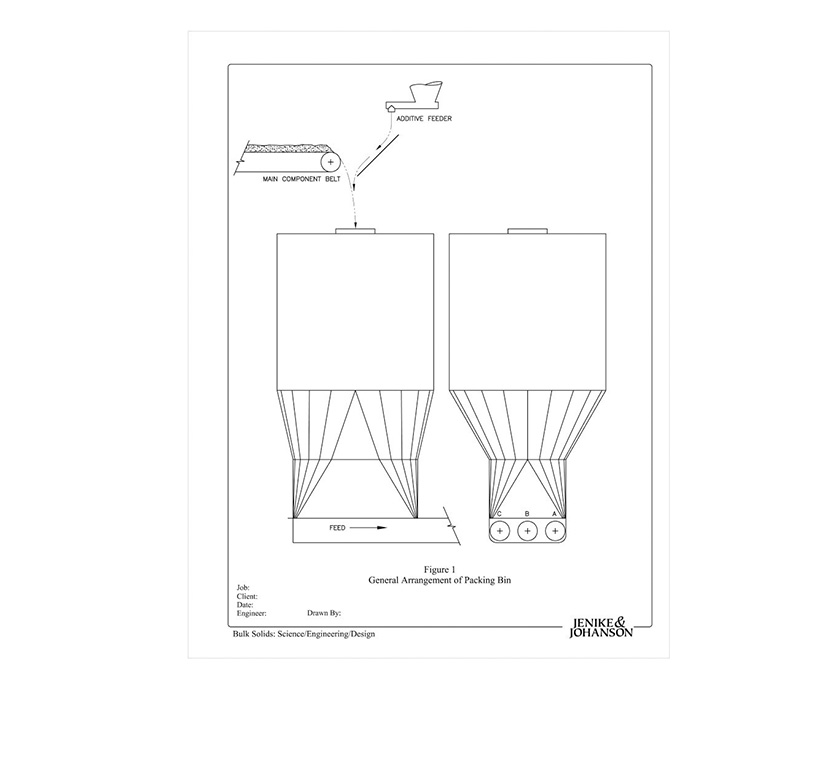

Functional vessel design.

Reinforced transition hopper.