Open House – Jenike & Johanson Canada is Turning 50!

Open House – Jenike & Johanson Canada is Turning 50!

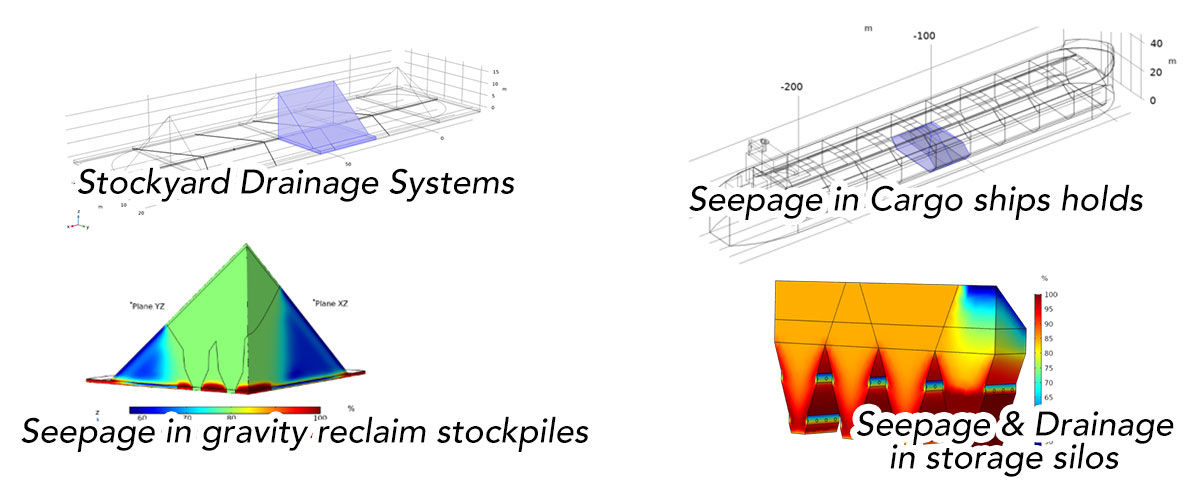

Stockpiles – Drainage/Seepage Analysis

Ores in a mine operation or port facility are required to be stacked in stockyards prior to handling or shipping since the arrival time is usually much shorter compared to their consumption time.

Buffer storage and homogenization piles are also necessary to take care of disruptions and/ or variability of the operation. These stockpiles typically range from a 7- to 45-day capacity. An important disadvantage is moisture infiltration into the stockpile as a result of long lasting and continuous rainfall. This affects flowability of the ore and, in some cases, slope stability. Ores having high moisture content can present significant problems in process steps downstream of the stockpile, for instance: liquefaction and flooding, MC (Moisture Content) above TML (Transportable Moisture Limit)

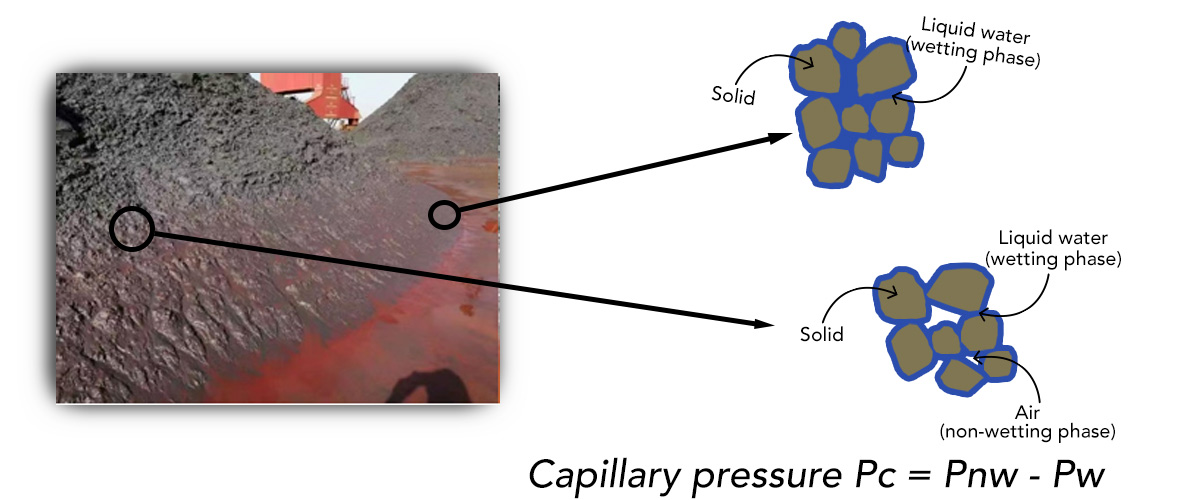

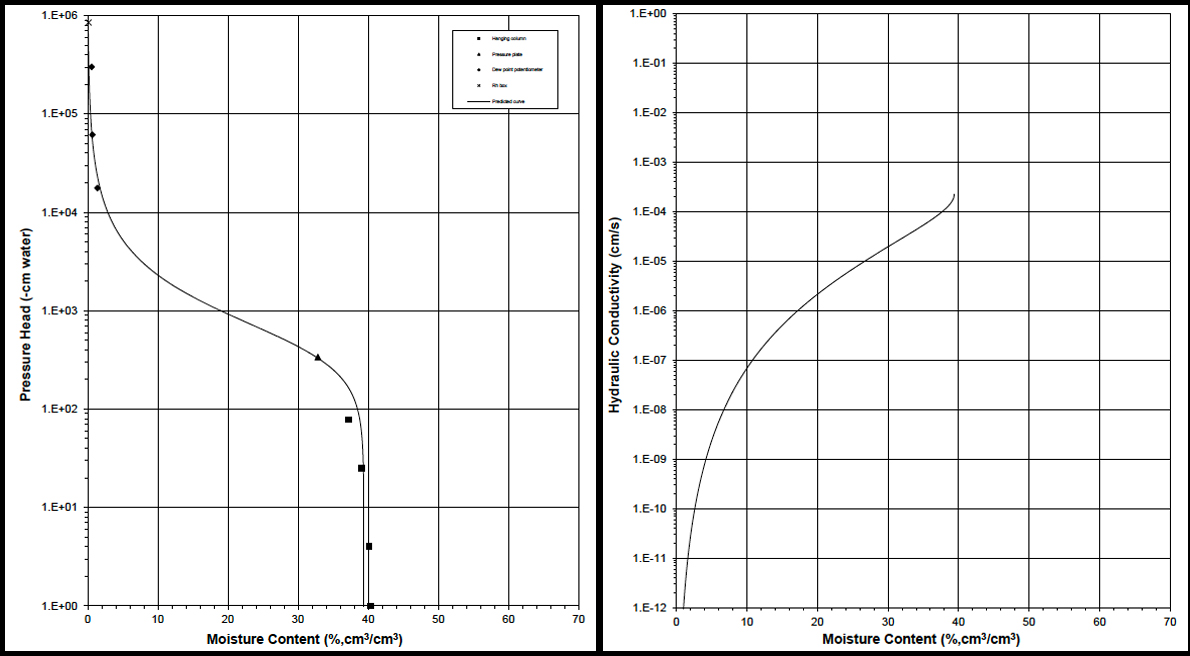

The water permeability of a partially-saturated porous material is a function of capillary pressure Pc. Functional relationships between saturation, capillary pressure and permeability must therefore be determined via laboratory tests to model unsaturated flow – saturated hydraulic conductivity and water retention and permeability properties.

The water permeability of a partially-saturated porous material is a function of capillary pressure Pc. Functional relationships between saturation, capillary pressure and permeability must therefore be determined via laboratory tests to model unsaturated flow – saturated hydraulic conductivity and water retention and permeability properties.