Open House – Jenike & Johanson Canada is Turning 50!

Open House – Jenike & Johanson Canada is Turning 50!

What are Silo or Equipment Failures?

Hundreds of industrial and farm silos, bins and hoppers experience some degree of failure each year due to improper design, faulty construction, and/or erratic operation.

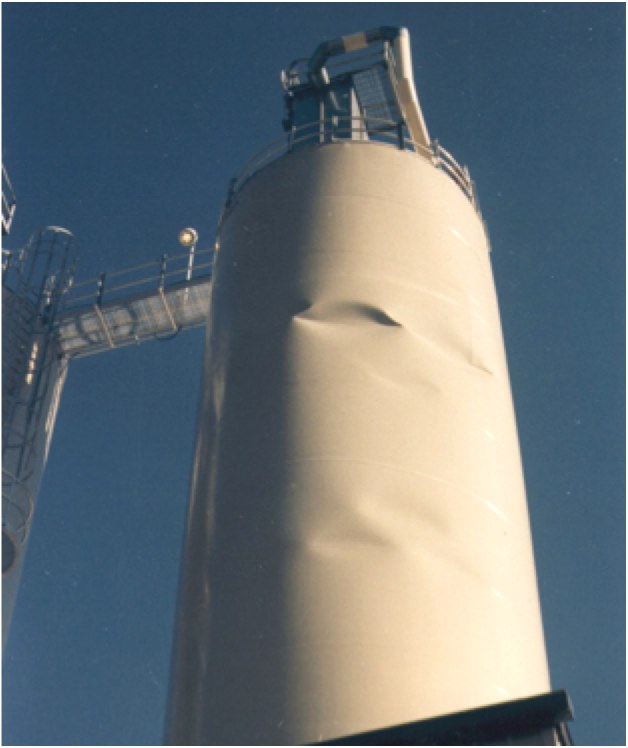

Although failure may involve a catastrophic collapse of the structure, it can also display in less obvious forms, such as cracks in a concrete wall, wrinkles/dents in a steel shell, and/or bending/deflection of a support beam. Even these more “minor” issues can be important danger signals, indicating that corrective measures are probably required.

Silo completely collapses.

Silo failure in shape of cluster wrinkles.

Major denting in silo.

Silo failure as the top of the vessel collapses.

Silo wrinkles may look minor, but can in fact lead to major production issues.

Corrosion around the silo can lead to a variety of issues.