The Need

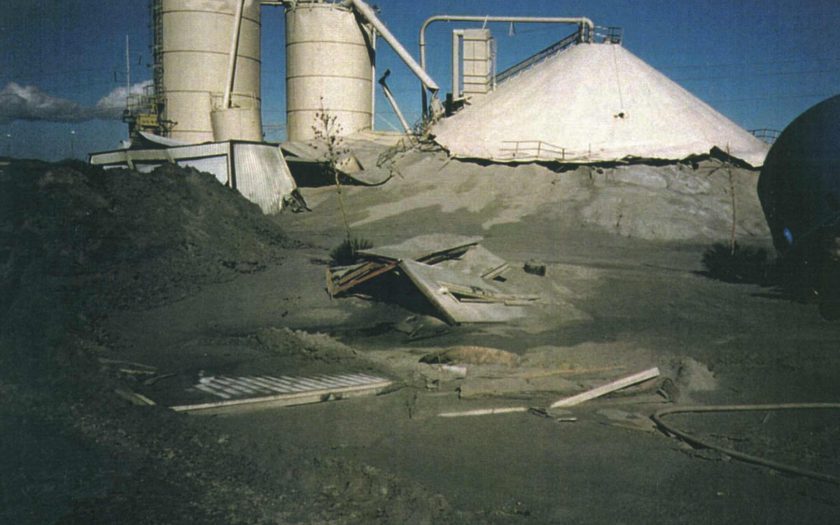

A new bolted steel storing 9,000 tons of fly ash from the adjacent coal fired power generation station split apart two weeks after it was first filled to capacity. Up to this point, no ash had ever been discharged. Curiously, the silo collapse occurred at night when the silo was being neither filled nor emptied.

The Solution

During the investigation into this failure, calculations showed that the silo was underdesigned and did not identify or account for a phenomenon called “Thermal Ratcheting”. The walls of outdoor metal silos expand during the day and contract at night as the temperature drops. If there is no discharge taking place and the material inside the silo is free flowing, it will settle as the silo expands. However, the material cannot be pushed back up when the silo walls contract, so it resists the contraction, which causes increased tensile stresses in the wall. The effect is repeated each day that the material sits at rest.

Also revealed were some cost-cutting measures taken by the silo supplier during the construction of the silo that contributed to the failure. The design specified that bolts of a particular classification, size and strength be used in the construction. These specified bolts have a distinct marking on their head that identifies them as having been tested and meeting recognized standards. Less than 1% of the bolts that were recovered from the failed fly ash silo had the specified marking and none of the marked bolts had been used in the critical vertical seams. Strength tests on the unmarked bolts revealed that some had tensile strengths less than the specified minimum.

The Result

There were many contributing factors to the collapse that acted together, and if any one had not been present, the collapse of the silo might have been avoided. If proper bolts had been purchased and used, the silo collapse may have been avoided. If the silo had been inspected by an independent silo expert, either during the construction or after construction was complete, perhaps the incorrect bolts would have been noticed and corrective action could have been taken. Had the operation of the silo been such that material was discharged more frequently, the condition of accumulated stresses that precipitated the collapse could have been prevented.

The life of a silo can be divided into three distinct phases:

- Design

- Construction

- Utilization

In each of these phases there are numerous opportunities for errors that can result in structural failure. As in the fly ash silo failure described above, the majority of structural failures of bins and silos can be attributed to a combination of several deficiencies or errors.