In my previous sections, I discussed the strengths and weaknesses of mechanical and pneumatic flow aids. The final category of flow aids, chemical flow aids, is the largest one simply because of the variety available.

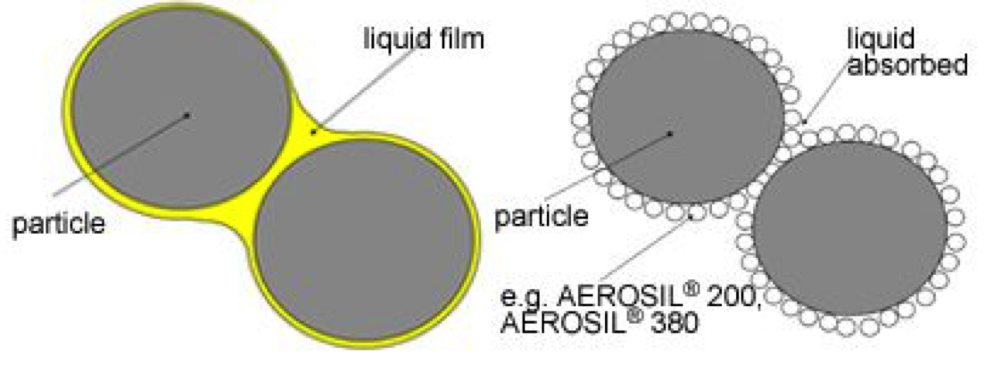

A number of chemicals have been used successfully as flow aids to alter the flow properties of bulk solids. These additives, in general, work by preventing the host particles from adhering to each other, which is accomplished by coating the surface of each particle, removing free moisture, or preventing the freezing of that moisture. Generally, these additives are dry powders, such as silicates, stearates, or phosphates but also could be liquids. Their effectiveness and the amount required can be easily determined by conducting cohesive strength tests on samples prepared in a lab.

Some of the considerations of this approach include the compatibility of the additive with the material handled and the process, the cost of the additive, and the cost of an additional handling system to deliver and mix the additive. Generally, this approach is considered to be one of the last resorts in solving a flow problem.

Some of the considerations of this approach include the compatibility of the additive with the material handled and the process, the cost of the additive, and the cost of an additional handling system to deliver and mix the additive. Generally, this approach is considered to be one of the last resorts in solving a flow problem.

This concludes my four-part blog series on flow aids. There are other types of flow aids not discussed here (including high pressure gas shells and sonic horns), and there are other ways to improve material flow (including inserts, retrofitting, and equipment redesign). Whatever method you choose, it is important that you make an informed decision with full knowledge of your material’s flow properties.