Fixed bed catalytic reactors, in which a gaseous reactant stream passes through a catalyst bed, is frequently used for synthesis, combustion, and effluent treatment. Radial flow reactors are preferred when a low pressure drop is desirable.

Fixed bed reactors can be operated continuously; however, they must be periodically shut down to replace deactivated catalyst with fresh catalyst. The resulting downtime and subsequent start-up time results in increased operating expenses and reduced efficiency.

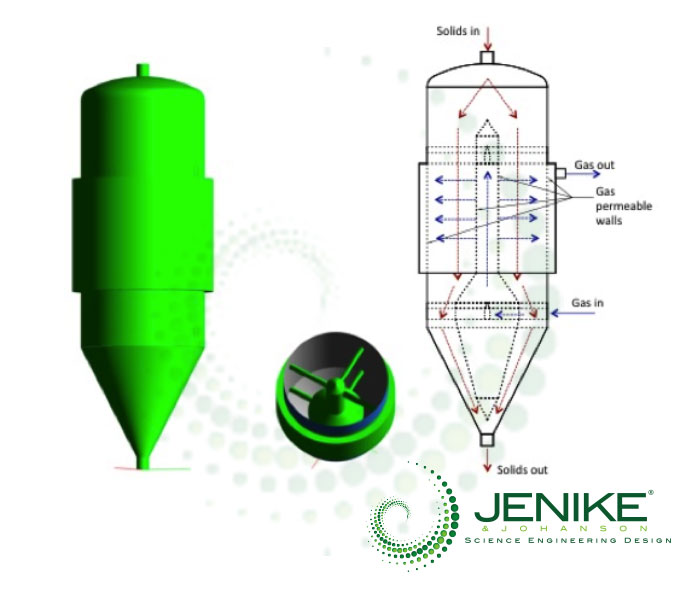

In contrast, moving bed catalytic reactors do not require expensive stoppages. In a radial flow moving bed reactor, a moving bed of catalyst flows downward in an annulus made up of permeable walls through which the gaseous reactant enters and the gaseous product leaves. Catalyst then enters a converging section and is discharged through a rotary valve. Because spent catalyst is continuously removed while fresh catalyst is added, shutdowns are unnecessary.

Moving bed radial flow reactors must be designed properly to ensure reliable flow of the catalyst. A mass flow solids flow pattern is required; that is, the walls of the converging section of the reactor must be steep enough and low enough in friction to ensure that the entire catalyst bed is in motion and no stagnant zones exist. In addition, the gas velocity must be low enough to prevent pinning, which can occur if the frictional force between the bulk solid and the permeable wall through which the gas exits prevents flow along the wall.

Jenike & Johanson’s radial flow moving bed reactor design is shown in the figure below. Jenike & Johanson uses a proven scientific approach based on the flow characteristics of the catalyst to ensure reliable flow of the solid catalyst and the gaseous reactants and products. Cohesive strength, wall friction, compressibility, and permeability tests are first conducted on samples of the catalyst. The test results are then used to calculate critical dimensions and the required slopes of the converging walls of the moving bed reactor.

To learn more about radial flow moving bed catalytic reactors, or if you have another application that involves the flow of solid reactants, please contact us.