Caking is a natural phenomenon. It could happen to your powder product whether you want it or not. If the caking is a quality problem that is resulting in multiple complaints, here is how you can determine the caking behavior of your material as well as important process variables to help you solve it.

A shear tester can be used to measure the caking behavior of powders simulating various conditions during storage at different periods of time at rest. This tester is used to measure the unconfined yield strength of a material under controlled levels of consolidation pressures. For example, to determine if a material will cake in a container after it has been stored for a week, the unconfined yield strength can be measured at consolidating pressures that correspond to those in the container. The temperature of the sample, and the ambient relative humidity can be controlled, if necessary.

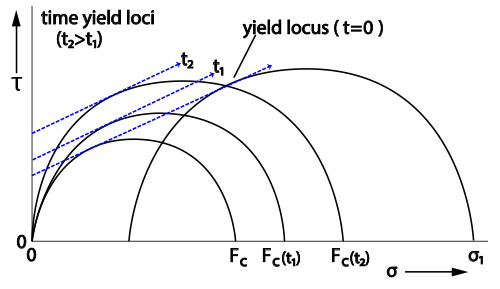

A shear cell of the Jenike shear tester is shown in Figure 1 below. The base of the shear cell is fixed to a stationary base plate. The shear ring is placed on the base. The base and ring contain the bulk solid specimen, which is covered with the shear lid. The shear lid and the bulk solid specimen are loaded centrically with a normal force, by means of a weight hanger. To shear the bulk solid, the shear ring and lid are moved horizontally by the stem. The stem is driven forward by a drive system at a steady rate. The measured shear force is transferred to the specimen through the bracket and the shear lid as well as through the small pin and the shear ring.

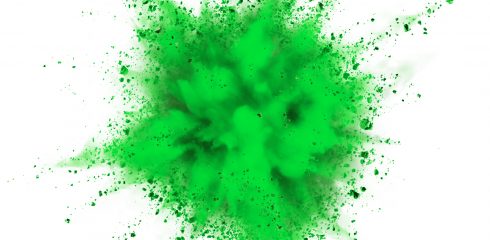

Prior to shearing, the bulk solid is consolidated to a predefined state by applying a normal load to the shear plane. The bulk solid is then brought to steady state condition. When the bulk solid is in the steady state condition, the normal load is decreased and the specimen sheared to instant failure. This process is repeated several times with different normal loads and a yield locus is obtained.

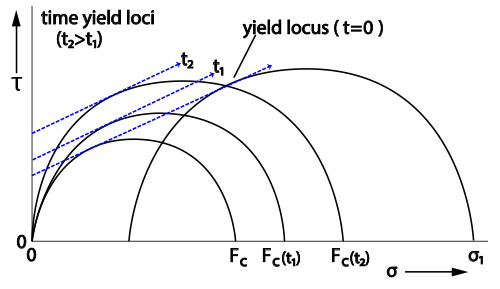

The unconfined yield strength denoted as fc or σc is obtained by construction of Mohr circles drawn tangentially to the yield locus. The point of intersection of a Mohr semi-circle with the sigma-axis determines the value of the major consolidating pressure σ1. The intersection of a Mohr semicircle with the sigma-axis drawn from the origin tangential to the yield locus defines the unconfined yield strength at instantaneous conditions (no time at rest).

Caking can be defined by the gain in the unconfined yield strength of a powder when held at consolidating pressures during a prescribed period of time. To evaluate the caking phenomenon, the powder is first consolidated in the shear cells under the instantaneous conditions described above, and the cells are placed in consolidation benches under a static load for a prescribed period of time and ambient conditions. The static load is the major consolidating pressure σ1. After the selected period of time expired, the cells are placed in the tester and sheared as described above.

The unconfined yield strength after a consolidation time is then estimated from measured yield loci by construction of Mohr stress circles (see Figure 2).

Be sure to contact a Jenike and Johanson engineer to help with any caking issues you may be experiencing!